Introduction

LED strip projects have become increasingly popular in recent years, thanks to their versatility, energy efficiency, and wide range of applications. However, to ensure a successful installation, it’s crucial to choose the right LED strip connector. With various types of connectors available, each with its own specifications and features, selecting the most suitable one for your project can be a daunting task. In this article, we’ll guide you through the process of choosing the right LED strip connector for your project, considering factors such as LED strip specifications, project requirements, connector type, material, and ease of installation.

Factors to Consider When Selecting an LED Strip Connector

1. LED Strip Specifications

When choosing an LED strip connector, the first step is to understand the specifications of your LED strip. Key specifications to consider include:

- Voltage: LED strips typically operate at either 12V or 24V. Ensure that the connector you choose matches the voltage of your LED strip to avoid any potential damage.

- Wattage: Different LED strips consume varying amounts of power. Check the wattage rating of your strip and select a connector that can handle the required load.

- Connector Type: Determine whether you need a male or female connector. This will depend on how you plan to connect the strips.

- Number of Pins: LED strips come with different pin configurations, such as 2-pin for single-color strips and 4-pin for RGB strips. Make sure to choose a connector that matches the pin configuration of your LED strip.

2. Project Requirements

Your project requirements will significantly influence your choice of LED strip connector. Consider the following factors:

- Indoor or Outdoor Use: If your project is intended for outdoor use, you’ll need connectors that are designed to withstand the elements. Look for waterproof connectors that can resist moisture and dust.

- Flexibility Needed: If your installation requires bending or twisting the LED strips, opt for flexible connectors that can accommodate movement without compromising the connection.

- Waterproofing Requirements: For projects in wet or humid environments, a waterproof connector is essential. These connectors often feature silicone gaskets or rubber seals to prevent water ingress.

- Aesthetic Considerations: Depending on your project’s design, you may want connectors that are less visible or blend seamlessly with the surroundings.

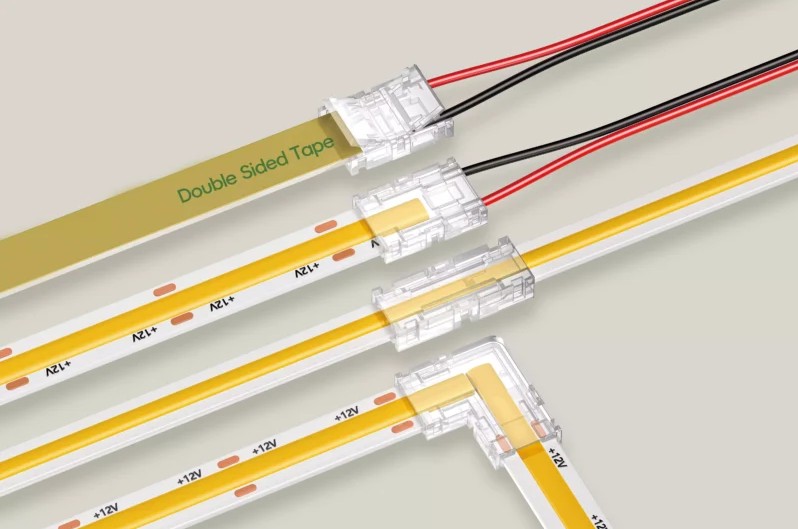

3. Connector Type

There are two main types of LED strip connectors: solderless and solder-on connectors. Each has its advantages and disadvantages:

- Solderless Connectors: These connectors allow for quick and easy installation without the need for soldering. They are ideal for DIY projects and temporary setups. However, they may not provide as secure a connection as solder-on connectors in high-stress environments.

- Solder-On Connectors: These connectors require soldering, providing a more permanent and secure connection. They are recommended for long-term installations where reliability is crucial.

4. Connector Material and Construction

The material and construction of the LED strip connector also play a vital role in its performance and durability:

- Plastic vs. Metal Connectors: Plastic connectors are lightweight and often more affordable, but they may not be as durable as metal connectors. Metal connectors, while heavier, offer better durability and heat resistance.

- Importance of Sturdy Construction: Choose connectors that are well-constructed to withstand wear and tear, especially in high-traffic or outdoor environments.

- Corrosion Resistance: If your project is outdoors or in a humid environment, select connectors that are corrosion-resistant to ensure a long-lasting connection.

5. Ease of Installation

The ease of installation is another critical factor to consider:

- Solderless Connectors: These connectors are designed for quick and hassle-free installation, making them suitable for beginners or those who prefer not to solder.

- Solder-On Connectors: While they require more skill and time to install, they provide a more reliable connection. Ensure you follow the manufacturer’s instructions for proper soldering techniques.

Common LED Strip Connector Types

1. 2-Pin Connectors

2-pin connectors are typically used for single-color LED strips. They are straightforward and easy to use, making them suitable for low-wattage applications. When sourcing these connectors, consider purchasing from a reputable LED strip connector manufacturer to ensure quality.

2. 4-Pin Connectors

4-pin connectors are essential for RGB LED strips, allowing for individual control of red, green, and blue LEDs. These connectors are ideal for higher-wattage applications and provide versatility in color mixing. When looking for a 4-pin connector, consult with a reliable LED strip connector supplier to find the best options.

3. Waterproof Connectors

Waterproof connectors are specifically designed for outdoor use or in areas with high moisture. They often feature silicone gaskets or rubber seals to prevent water ingress, ensuring a reliable connection even in harsh environments. When selecting waterproof connectors, make sure to verify their IP rating to ensure they meet your project’s requirements.

Tips for Choosing the Right Connector

- Match the Connector Type: Ensure the connector type aligns with the specifications of your LED strip. This includes voltage, wattage, and pin configuration.

- Consider Project Requirements: Evaluate whether your project is indoor or outdoor, and choose connectors that meet those specific needs.

- Check Compatibility: Confirm that the connector is compatible with your LED strip’s voltage and wattage to avoid any issues during installation.

- Select Quality Materials: Opt for connectors made from durable materials that can withstand environmental factors, especially if used outdoors.

- Follow Manufacturer Instructions: Always adhere to the installation guidelines provided by the manufacturer to ensure a secure and reliable connection.

Conclusion

Choosing the right LED strip connector for your project is crucial for ensuring a successful installation. By considering factors such as LED strip specifications, project requirements, connector type, material, and ease of installation, you can make an informed decision. Whether you are looking for a solderless solution for a quick DIY project or a robust solder-on connector for a permanent installation, understanding these elements will help you find the perfect LED strip connector. Remember to consult with reputable LED strip connector manufacturers and suppliers to ensure you are getting high-quality products that meet your needs. With the right connector, your LED strip project will shine brightly and function flawlessly for years to come.