Introduction

Integrating LED strip connectors with dimmable systems can be complex, but it’s essential for achieving optimal performance in LED lighting setups. LED strip connectors are crucial components that ensure LED strips’ proper connection and functionality. Understanding the challenges and how to address them is vital for anyone purchasing and installing these systems.

This article will explore the common challenges and provide solutions to help users make informed decisions when selecting an LED strip connector, whether they are dealing with an LED strip connector manufacturer or an LED strip connector supplier.

Understanding LED Strip Connectors

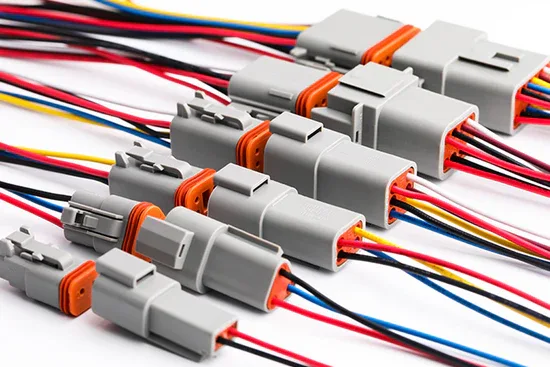

LED strip connectors come in various types, including solderless, soldered, and snap-on. These connectors create seamless connections between LED strips, power supplies, and controllers. They play a vital role in ensuring the electrical and mechanical integrity of the LED strip system.

Typical applications range from residential lighting projects to commercial installations, where the reliability and performance of the connectors can significantly impact the overall system’s functionality.

Challenges in Integration with Dimmable Systems

1.Compatibility Issues

Comp compatibility is one of the primary challenges in integrating LED strip connectors with dimmable systems. With various connector types and dimmer specifications on the market, ensuring that the connectors and dimmers match voltage and current ratings is critical.

Mismatched components can lead to poor performance, flickering, or even damage to the LED strips. It’s important to carefully check the specifications provided by the LED strip connector manufacturer and the dimmer to ensure compatibility.

2.Signal Integrity and Control

Maintaining consistent signal quality is another significant challenge. Dimmable systems rely on precise control signals to adjust the brightness of the LED strips. Any interference or loss of signal can result in uneven dimming or complete failure of the dimming function.

High-quality connectors that minimize signal degradation are essential. Additionally, proper installation techniques and shielding can help maintain signal integrity.

3.Installation Complexity

The installation process for LED strip connectors can be complex, especially for those unfamiliar with the intricacies of these systems. Achieving reliable connections often requires careful attention to detail.

Common mistakes include improper seating of connectors, incorrect wiring, and inadequate securing of connections. Following best practices and guidelines from the LED strip connector supplier can help avoid these issues and ensure a successful installation.

4.Heat Management

Dimming LED strips can affect heat generation, as reducing the brightness can concentrate heat in certain areas. This can pose a challenge for connectors, which must handle the thermal load without degrading. Ensuring that connectors can manage the heat effectively is crucial for the longevity and performance of the system. This involves selecting connectors with good thermal properties and incorporating additional cooling measures.

Solutions to Overcome Integration Challenges

1.Selecting the Right Components

Choosing the right components is the first step in overcoming integration challenges. When selecting an LED strip connector, it’s essential to ensure compatibility with both the LED strips and the dimmer. This involves checking the voltage, current ratings, and other specifications.

Opt for connectors from reputable LED strip connector manufacturers and suppliers to ensure quality and reliability. Reading reviews and seeking recommendations can also help in making an informed decision.

2.Proper Installation Techniques

Proper installation is critical to integrating LED strip connectors with dimmable systems. Here are some steps and tips to follow:

1.Preparation: Gather all necessary tools and materials before starting the installation. This includes wire cutters, strippers, and appropriate connectors.

2.Connections: Ensure that all connections are secure and properly seated. Double-check polarity and wiring to prevent errors.

3.Testing: Before finalizing the installation, test the connections to ensure they work as expected. This can help identify any issues early on.

4.Documentation: Refer to the installation guidelines provided by the LED strip connector supplier. These documents often contain valuable information and tips to avoid common pitfalls.

3.Ensuring Signal Quality

To maintain signal quality, consider the following approaches:

1.Signal Amplifiers: If the length of the LED strip exceeds the recommended limits, use signal amplifiers or boosters. This helps maintain consistent control signals.

2.Shielding: Properly route and shield wires to minimize interference. This is particularly important in environments with a lot of electronic noise.

3.Regular Maintenance: Perform regular checks and maintenance to ensure all connections remain secure and free from corrosion or damage.

4.Managing Heat Effectively

Effective heat management is crucial for the longevity of LED strip connectors in dimmable systems. Here are some strategies:

1.Heat Sinks: Incorporate heat sinks or other cooling solutions to dissipate heat away from the connectors.

2.Ventilation: Ensure proper ventilation around the LED strips and connectors to prevent overheating.

3.Temperature Monitoring: Use connectors with built-in thermal protection or add temperature sensors to monitor and manage heat.

Case Studies and Examples

Real-world examples can provide valuable insights into successful integrations. Here are a few scenarios:

1.Residential Lighting: In a home renovation project, an LED strip connector supplier provided high-quality connectors that ensured seamless dimming and reliable performance.

2.Commercial Installations: A commercial building used advanced connectors from a reputable LED strip connector manufacturer. This helped maintain signal integrity and manage heat effectively, resulting in a long-lasting lighting solution.

3.Custom Installations: In a custom lighting setup, careful selection and proper installation of connectors allowed for precise dimming control and enhanced aesthetic appeal.

Conclusion

Integrating LED strip connectors with dimmable systems presents several challenges, including compatibility issues, signal integrity, installation complexity, and heat management.

However, these challenges can be overcome by selecting the right components, following proper installation techniques, ensuring signal quality, and managing heat effectively. Consulting with experts and relying on reputable LED strip connector manufacturers and suppliers can further enhance the success of your LED lighting projects.