Service

Wiring Harness Processing Services

To satisfy the needs of different clients, our organization provides thorough wiring harness processing services that include the following areas

Wire Cutting

- Precision Length Cutting: We reduce mistakes and increase production efficiency by ensuring every wire cut is the exact length we need.

- Handling Various Wire Gauges: Wires of all gauges—from massive cables for many uses to thin electronic wires—are processed.

Wire Stripping

- Automatic Wire Stripping: We do fast and accurate stripping by predefined parameters with automatic wire stripping machines, perfect for mass production.

- Manual Wire Stripping: For wires having special or complicated requirements, our professionals may carefully strip them by hand, guaranteeing accuracy and quality.

Crimping

- Terminal Crimping: WeUtilizing guarantee safe and dependable electrical connections by using specialist terminal crimping tools.

- Plug Crimping: Our expert crimping services for different plugs guarantee steady electrical functioning.

- Custom Die Molding: The finest crimping results are guaranteed by custom crimping dies made and developed according to customer specifications.

Welding

- Manual Welding: Our skilled welders do meticulous manual welding for small-batch production and high-precision needs.

- Automatic Welding: Using automated welding technology, perfect for large production, we guarantee consistency and dependability.

- Soldering: used extensively in electronic harnesses for good mechanical strength and electrical contact.

- Ultrasonic Welding: Using high-frequency vibrations to unite two materials creates a strong, durable, and fast weld suitable for metal and plastic harnesses.

Harness Assembly

- Modular Assembly: We build modular harnesses using design drawings or samples supplied by the customer, ensuring that every component is positioned and connected precisely.

- Complex Harness Customization: We manage branching harnesses, shielded harnesses, multi-core harnesses, and other intricate designs to suit various application requirements.

- Sample Production and Mass Production: Providing complete process services to guarantee the quality and consistency of the products from sample to mass manufacture.

Harness Testing

- Electrical Performance Testing: To be sure harnesses satisfy design specifications, test their continuity, resistance, insulation, and other electrical characteristics.

- High Voltage Testing: Testing high voltage to guarantee dependability and safety in industrial settings.

- Functional Testing: Realistic operating situations are simulated for thorough functional testing to guarantee proper operation of the harnesses.

Injection Molding

- Overmolding: Using injection moulding equipment to over-mould, harnesses become more robust and protective.

- Plug and Connector Molding: Offering services for injection moulding different plugs and connectors to guarantee a tight connection with the harness.

- Custom Mold Design: creating and building bespoke injection moulds to suit specific applications and shape requirements to client specifications.

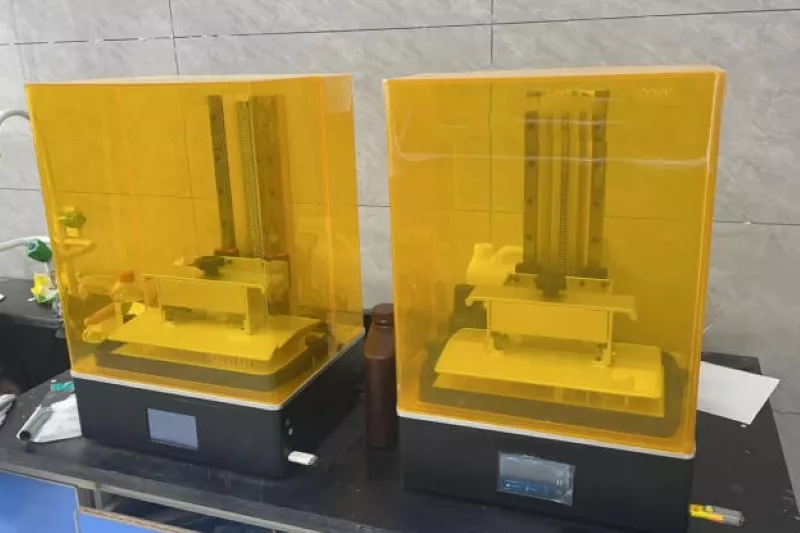

3D Printing Samples

- Customized Printing: Providing bespoke 3D printing services with great consistency in the finished result based on design drawings or customer CAD files.

- Rapid Prototyping: Using cutting-edge 3D printing technology, clients can examine the finished product fast, confirm physical characteristics, evaluate design viability and functioning, and swiftly spot and fix possible problems.

- Small Batch Production: We can print single samples and small batches to satisfy clients that need customized goods in small quantities.

- Display and Evaluation: Displaying and evaluating 3D printed examples can help consumers and potential purchasers better comprehend the product and boost market adoption.

- Our commitment is to offer practical, high-quality solutions to satisfy various client requirements in different application domains. Our customers get the best wiring harness processing services because we guarantee the quality and efficiency of every production process using cutting-edge technology and a qualified technical staff.

Custom Options

Our organization provides a range of customizable alternatives to satisfy the unique demands of various clients, guaranteeing that each wire harness precisely satisfies the client's specifications. Our primary customization choices are shown below