Introduction

LED light connectors play a crucial role in the functionality and efficiency of LED lighting systems. Whether you’re embarking on a residential lighting project or overseeing a large-scale commercial installation, selecting the correct connector type is paramount to ensure optimal performance and longevity of your LED lights.

In this comprehensive guide, we’ll explore the various types of LED light connectors available on the market, discussing their features, applications, and considerations for choosing the most suitable option for your specific needs.

Common Types of LED Light Connectors

Screw-On Connectors

Screw-on connectors are one of the most traditional types of LED light connectors. They feature threads allowing a secure connection between the LED light and the power source. These connectors are commonly used in household lighting fixtures and outdoor applications where a reliable and durable connection is essential. While they offer a firm grip and stability, screw-on connectors may require more time for installation and are less convenient for frequent disconnections.

Push-In Connectors

Push-in or plug-and-play connectors are designed for quick and easy installation. They feature a simple push-in mechanism that allows the LED light to be connected to the power source without needing tools or twisting. Push-in connectors are ideal for applications requiring rapid installation and disassembly, such as temporary lighting setups or stage productions. However, they may not provide as secure a connection as screw-on connectors and are more susceptible to accidental disconnections.

Soldered Connectors

Soldered connectors involve permanently joining the wires of the LED light to the power source using soldering techniques. This method ensures a robust and reliable connection that is resistant to vibrations and environmental factors. Soldered connectors are commonly used in automotive lighting, electronics, and industrial applications where stability and durability are paramount. However, soldering requires specialized skills and equipment, making it less suitable for DIY projects or applications requiring frequent modifications.

Crimp-On Connectors

Crimp-on connectors utilize a crimping tool to attach the wires of the LED light to the connector terminals. This method offers a secure and durable connection without soldering or twisting. Crimp-on connectors are widely used in commercial and industrial lighting installations as well as automotive and marine applications. They provide excellent conductivity and are corrosion-resistant, making them suitable for outdoor and harsh environments. However, crimping requires precision and care to ensure proper alignment and compression of the connector.

Specialized Types of LED Light Connectors

Waterproof Connectors

Waterproof connectors are specially designed to withstand exposure to moisture, humidity, and other environmental elements. They feature sealing mechanisms, such as rubber gaskets or silicone seals, that prevent water ingress and corrosion. Waterproof connectors are commonly used in outdoor lighting fixtures, underwater applications, and industrial environments where moisture resistance is essential. They provide reliable performance in challenging conditions but may require additional precautions during installation to ensure proper sealing.

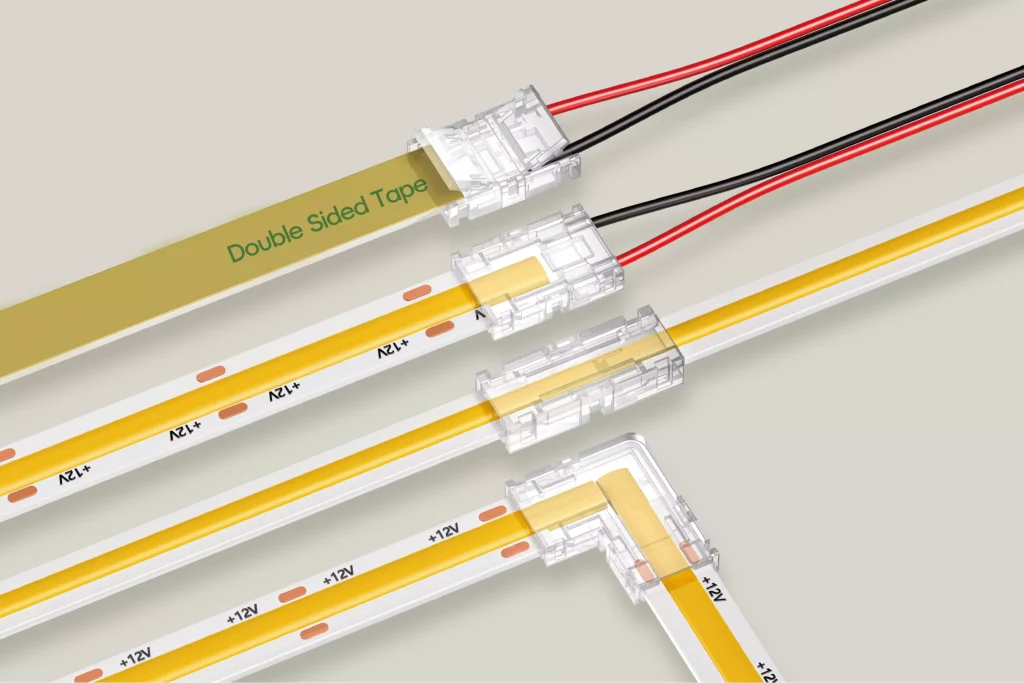

Quick Connectors

Quick or snap-on connectors offer a convenient and tool-free solution for connecting LED lights to power sources. They feature spring-loaded mechanisms allowing easy attachment and connector removal without twisting or soldering. Quick connectors are ideal for frequent reconfiguration or maintenance applications, such as retail displays, signage, and modular lighting systems. However, they may not provide as secure a connection as screw-on or soldered connectors and are more prone to wear and tear over time.

Twist-On Connectors

Twist-on connectors, called wire nuts or wires, are famous for joining multiple wires. They feature a threaded cap that twists onto the cables, creating a tight and secure connection. Twist-on connectors are commonly used in residential and commercial lighting installations, electrical wiring, and DIY projects. They offer simplicity and versatility, allowing for easy installation and reconfiguration without specialized tools. However, twist-on connectors may not provide as robust a connection as soldered or crimped connectors and are unsuitable for high-vibration or high-temperature environments.

Factors to Consider When Choosing LED Light Connectors

Selecting the right LED light connector involves considering various factors to ensure compatibility, reliability, and ease of installation. Some key factors to keep in mind include:

- Compatibility with LED lights: Ensure that the connector is compatible with your LED lights’ voltage, current, and wiring configuration.

- Electrical specifications: Consider the connector’s electrical rating, insulation material, and conductor size to ensure safe and efficient operation.

- Environmental conditions: Choose connectors suitable for the intended application environment, such as indoor, outdoor, wet, or hazardous locations.

- Ease of installation: Select connectors that offer easy installation and maintenance, considering factors such as tool requirements, accessibility, and connector design.

- Cost-effectiveness: Evaluate the overall cost of the connector, including upfront purchase price, installation time, and long-term maintenance, to ensure cost-effective solutions for your project.

Tips for Selecting the Right LED Light Connector

When selecting LED light connectors for your project, consider the following tips to ensure optimal performance and compatibility:

- Assess specific project requirements: Identify the unique needs and constraints of your project, such as power requirements, installation environment, and budget considerations.

- Consult with experts or suppliers: Seek advice from experienced professionals or reputable suppliers who can provide guidance and recommendations based on your project specifications.

- Test compatibility before deployment: Conduct thorough testing and compatibility checks with your LED lights and power sources before deploying connectors on a large scale to avoid compatibility issues and ensure seamless integration.

Conclusion

In conclusion, LED light connectors come in various types and configurations to suit different applications and requirements. Whether you’re looking for a secure and durable connection for industrial lighting or a quick and convenient solution for temporary installations, there’s a connector available to meet your needs. By understanding the different types of connectors, considering key factors, and following best practices for selection and installation, you can ensure your LED lighting systems’ reliable performance and longevity.