1. Introduction: The Critical Role of LED Strip Connectors

Modern lighting systems depend on LED strip connectors to deliver stable power and precise signal control. These components are the backbone of commercial signage, architectural lighting, and smart home setups. For professionals, choosing between 2-pin LED strip connectors and 4-pin LED strip connectors directly impacts system performance, scalability, and maintenance costs. This guide dissects technical specifications, explores RGB LED strip connectors, evaluates waterproof LED strip connectors, and reveals quality benchmarks in LED strip connectors manufacture.

2. Core Technical Concepts: How LED Strips and Connectors Work

2.1 Electrical Fundamentals

- Voltage Requirements: 12V (residential) vs 24V (industrial) DC systems

- Current Capacity: 2-pin connectors (3-6A) vs 4-pin variants (6-10A)

- Polarity Management: Keyed housings to prevent reverse connections

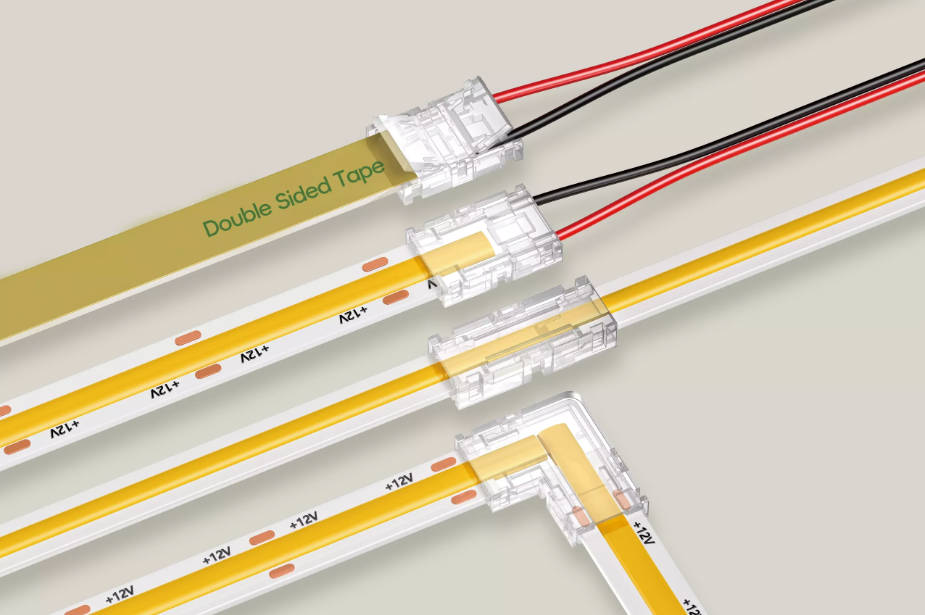

2.2 Connector Taxonomy

| Type | Pins | Applications |

| 2-Pin | +V, GND | Monochromatic strips |

| 4-Pin RGB | R, G, B, +V | Dynamic color systems |

| Waterproof IP67 | Sealed | Outdoor/pool lighting |

3. 2-Pin LED Strip Connectors: Technical Breakdown

3.1 Electrical Specifications

- Voltage Compatibility: Dual-rated for 12V/24V systems

- Current Limits:

- Standard models: 3A (18AWG wire)

- Heavy-duty models: 6A (16AWG stranded copper)

- Certifications: UL 1977, IEC 60598-2-20

3.2 Industrial Use Cases

- Warehouse Lighting: 5000K strips with 150 lm/W efficiency

- Retail Displays: <3% voltage drop over 10-meter runs

- Case Study: 24V 2-pin system reducing wiring costs by 40% vs traditional AC lighting

4. 4-Pin RGB LED Strip Connectors: Advanced Control Systems

4.1 RGB Control Architecture

- PWM Dimming: 1KHz frequency for flicker-free operation

- Signal Protocols: SPI (WS2812B), DMX512, DALI

- Thermal Design: Aluminum PCBs for 10°C temperature reduction

4.2 Installation Challenges

- Voltage Drop Mitigation: 5V vs 12V RGB systems

- Signal Integrity: Twisted-pair wiring for EMI reduction

- Power Budgeting: 60W/m max for high-density addressable strips

5. Waterproof LED Strip Connectors: Durability Engineering

5.1 IP Rating Standards

| IP Code | Protection Level | Applications |

| IP20 | Basic indoor | Drywall installations |

| IP65 | Dustproof + water jets | Kitchens/bathrooms |

| IP67 | 30-minute submersion | Pool/fountain lighting |

5.2 Material Innovations

- Gasket Design: Silicone seals with 35% compression ratio

- Housing Materials: UV-stabilized polycarbonate (125°C rating)

- Corrosion Resistance: Salt spray tested per ASTM B117

6. LED Strip Connectors Manufacturing: Quality Assurance

6.1 Production Process

- Contact Stamping: Phosphor bronze terminals (15μm gold plating)

- Overmolding: Flame-retardant PVC (UL94 V-0 rating)

- Testing: 1500VAC dielectric strength, 10,000 mating cycles

6.2 Compliance Metrics

- Safety: UL 1977, CE, RoHS 2.0

- Performance: 0.5mΩ max contact resistance

- Durability: -40°C to 105°C operational range

7. Installation Best Practices for Professionals

7.1 Voltage Drop Calculations

Max Run (meters) = (Supply Voltage – LED Voltage) / (Current per LED × LEDs/m × Wire Resistance/m)

Example: 12V system with 3.4V LEDs, 60mA/LED, 0.016Ω/m wire → 8.2m max

7.2 Signal Integrity Management

- Twisted Pair Wiring: 22AWG for RGB control lines

- Ferrite Beads: 100MHz noise suppression

- Ground Separation: Star topology to prevent loops

8. Troubleshooting Common Issues

| Symptom | 2-Pin Diagnosis | 4-Pin Solution |

| Intermittent Power | Loose crimp terminals | Check PWM controller ground |

| Color Flickering | N/A | Shield control lines |

| Connector Overheat | Upgrade to 14AWG wire | Add heatsinks to drivers |

9. Future Trends in LED Connectivity

- PoE Integration: 802.3bt standard delivering 90W via Ethernet

- Smart Connectors: Built-in temperature/current sensors

- Modular Systems: Tool-less connectors for field adjustments

10. Conclusion: Optimizing LED Strip Installations

2-pin LED strip connectors remain ideal for cost-sensitive single-color projects, while 4-pin RGB LED strip connectors enable advanced color scenarios. Always specify waterproof LED strip connectors for outdoor/exterior use and audit suppliers’ LED strip connectors manufacture processes for mission-critical applications. As hybrid power-data systems evolve, prioritize connectors with forward compatibility and IoT readiness.