1. Introduction to JST XH Connectors in LED Applications

LED lighting has revolutionized illumination, offering unparalleled efficiency, longevity, and design flexibility. However, the seamless operation of any LED system hinges on reliable interconnections. This is where JST XH Connector Cables play a pivotal role. Known for their compact design and secure connections, these humble components are the unsung heroes behind countless brilliant LED installations.

JST (Japan Solderless Terminals) is a globally recognized manufacturer of high-quality connectors. Among their extensive product line, the XH series stands out as a go-to solution for applications demanding a 2.5mm pitch. Its popularity in the LED sector stems from its ability to provide a secure and compact electrical link, crucial for the intricate and often space-constrained nature of LED circuitry.

Why are JST XH connectors so crucial for LED lighting? Simply put, they offer a perfect blend of reliability, affordability, and a small footprint – attributes highly sought after in modern LED designs. Whether you’re dealing with delicate LED strips, complex modules, or compact drivers, JST XH connectors provide a consistent and dependable electrical path, ensuring optimal performance and longevity of your lighting system. From hobbyist projects to large-scale commercial installations, understanding the capabilities of JST XH Connector Cables is essential for anyone working with LED technology.

2. Technical Specifications and Advantages of JST XH Connectors

Delving deeper into the technical aspects reveals why JST XH connectors are so well-suited for LED applications. Their core specifications are tailored to meet the demands of low-power electronic connections, which are characteristic of many LED setups.

Detailed Specifications:

| Specification | Value | Implication for LED Lighting |

| Pitch | 2.5mm (0.098 inches) | Allows for high-density mounting on PCBs, crucial for compact LED modules and fixtures. |

| Current Rating | Up to 3A AC/DC | Sufficient for powering individual LED strips or small to medium LED arrays. Always check specific datasheet. |

| Voltage Rating | Up to 250V AC/DC | Handles standard low-voltage LED driver outputs. |

| Temperature Range | -25°C to +85°C | Suitable for most indoor and some outdoor non-extreme LED environments. |

| Insulation Resist. | 1000MΩ min. | Ensures minimal current leakage, promoting efficiency and safety. |

| Contact Resist. | 10mΩ max. | Low resistance ensures efficient power transfer and minimal heat generation at the connection point. |

| Housing Material | PA66 (Nylon 6/6) | Offers good insulation properties, durability, and resistance to common solvents. |

| Contact Material | Phosphor Bronze | Provides excellent conductivity and spring properties for reliable mating and unmating cycles. |

Key Advantages for LED Systems:

- Space-Saving Design: The 2.5mm pitch is a significant advantage, allowing for extremely compact designs. This is vital for applications like thin LED light bars, integrated LED modules, and smart lighting devices where space is at a premium.

- Secure and Reliable Connection: The JST XH series features a friction lock mechanism. This simple yet effective design ensures that once mated, the connector provides a firm and reliable connection, highly resistant to vibrations and accidental disconnections – a common concern in dynamic lighting environments or applications involving movement.

- Ease of Assembly and Disassembly: For JST XH Connector Cables manufacture, ease of use is paramount. These connectors are designed for straightforward crimping and insertion, which speeds up assembly lines and reduces labor costs. For end-users, they’re also easy to disconnect and reconnect, simplifying installation, maintenance, and troubleshooting.

- Cost-Effectiveness: JST XH connectors strike an excellent balance between performance and price. They are an economical choice for mass-produced LED products, allowing manufacturers to maintain competitive pricing without compromising on connection quality.

- Versatility: Available in a wide range of pin counts (from 2 to 20 pins), JST XH connectors can accommodate various LED configurations. This includes simple power connections, multi-channel RGB or RGBW control, and even data lines for addressable LEDs.

3. Common Applications of JST XH Connector Cables in LED Lighting

The versatility and reliability of JST XH Connector Cables have made them ubiquitous across numerous LED lighting applications. From decorative accents to essential industrial illumination, their presence ensures seamless power and signal delivery.

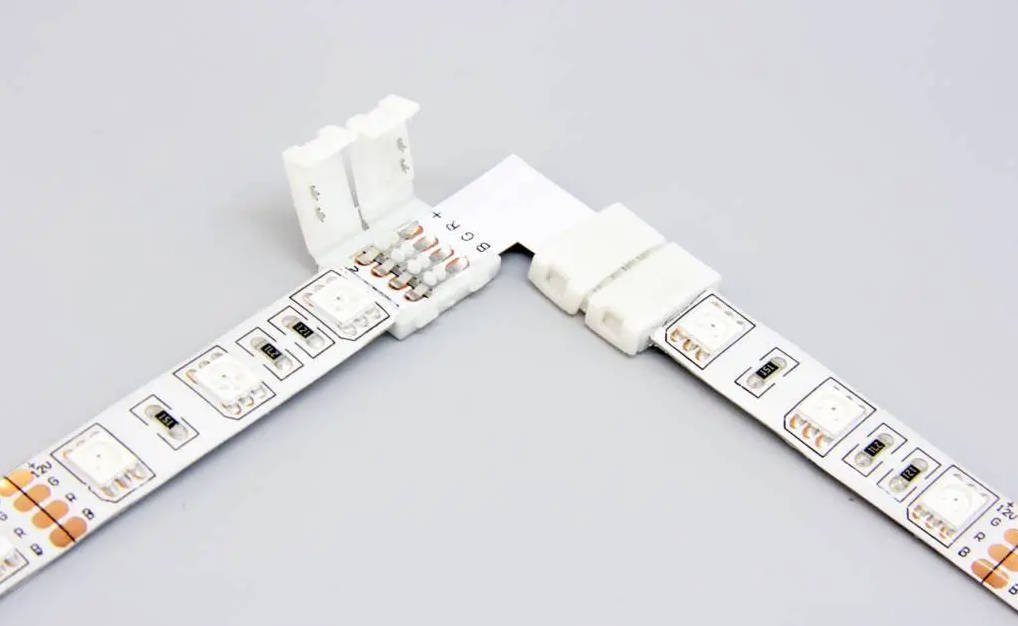

- LED Strips and Modules: This is arguably the most common application. JST XH connectors are widely used for:

- Connecting power from a driver or power supply to individual LED strips.

- Interconnecting multiple LED modules in series or parallel, enabling custom lengths and configurations.

- Signal transmission for addressable LED strips (e.g., WS2811, WS2812B, SK6812), carrying data signals for complex lighting effects.

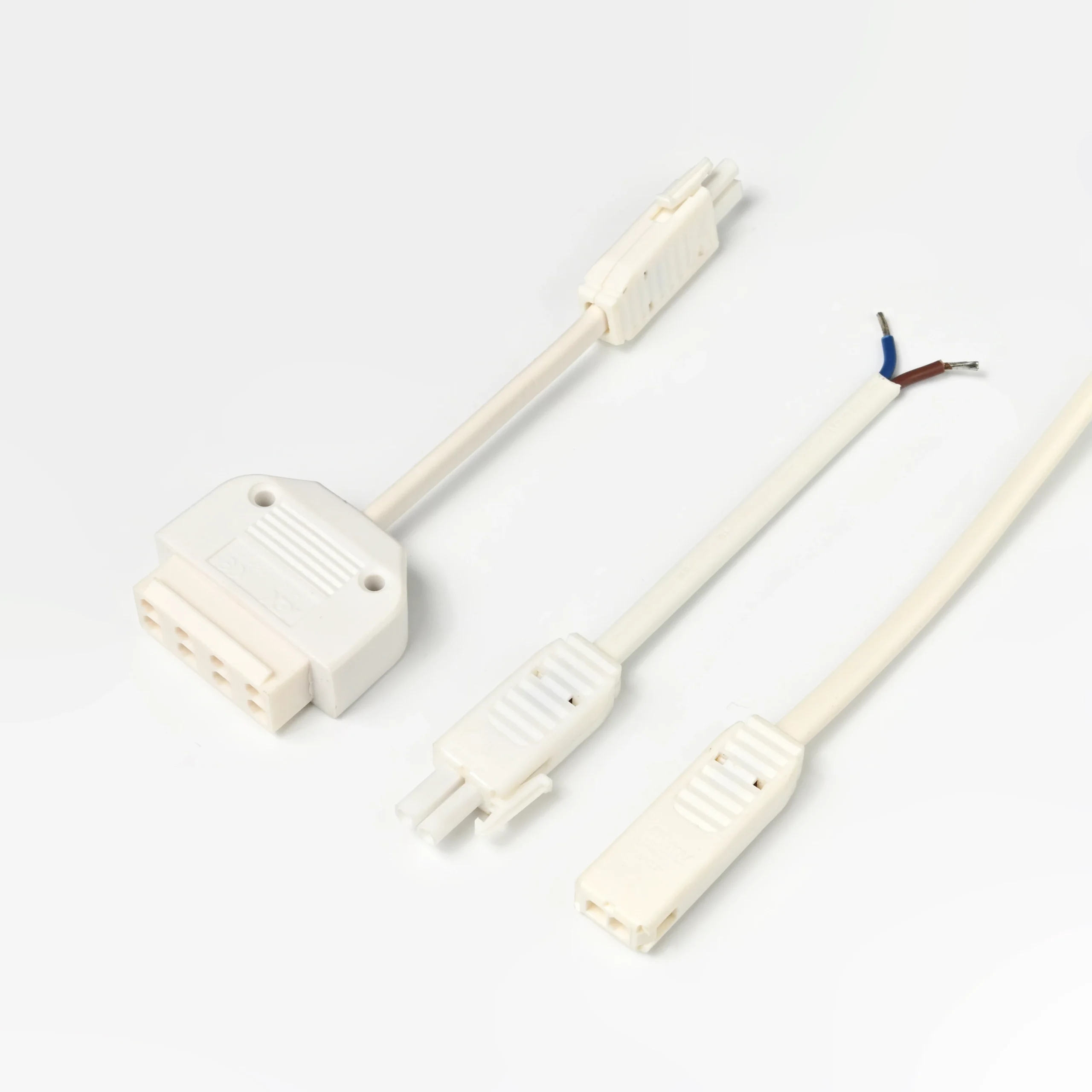

- LED Drivers and Power Supplies: Many compact LED drivers and power supplies feature JST XH outputs for direct connection to LED loads. This simplifies wiring and ensures a standardized interface. They are often found on the low-voltage DC output side, providing a neat and secure link to the LEDs.

- Architectural and Decorative LED Lighting: In applications like under-cabinet lighting, cove lighting, and display lighting, the discreet size of JST XH connectors is a major advantage. They allow for clean wiring that blends seamlessly with the environment, enhancing the aesthetic appeal of the lighting installation.

- Automotive and Marine LED Lighting: While requiring additional environmental sealing for harsh conditions, the inherent reliability of the JST XH connection makes it a candidate for internal wiring in automotive and marine LED fixtures where vibration is a concern. Their compact nature also helps in tight spaces within vehicles and boats.

- DIY and Hobbyist LED Projects: For enthusiasts and makers, JST XH Connector Cables are a dream to work with. Their ease of crimping and reliable connection make them perfect for prototyping custom LED setups, creating wearable tech, or integrating LEDs into robotics. This accessibility is a key reason why so many turn to a JST XH Connector Cables supplier for their projects.

4. Addressing Common User Concerns and FAQs

Even with their widespread use, users often have specific questions about JST XH connectors. Addressing these common concerns ensures proper usage and maximizes the longevity of your LED system.

- “What is the maximum current/voltage I can put through a JST XH connector for my LEDs?”

- While JST XH connectors are rated up to 3A and 250V AC/DC, it’s crucial to consult the specific JST datasheet for the exact part number you are using. Real-world current capabilities can be influenced by wire gauge, ambient temperature, and the number of pins carrying current. For continuous operation, it’s often advisable to derate the current by 20-30% to ensure optimal performance and prevent overheating. For instance, if you have a high-power LED array drawing 2.5A, a JST XH connector might be close to its limit, and a larger gauge wire or a connector with a higher rating might be more appropriate.

- “Are JST XH connectors suitable for outdoor LED applications?”

- Standard JST XH connectors are generally not rated for outdoor use or exposure to moisture and dust. They do not possess an IP (Ingress Protection) rating for water or dust resistance. For outdoor or harsh environments, you would need to incorporate additional waterproofing solutions, such as heat-shrink tubing with adhesive lining, epoxy potting, or enclosures with appropriate IP ratings. For directly exposed connections, consider specialized, weather-sealed connectors.

- “How do I properly crimp and assemble JST XH connector cables?”

- Proper crimping is paramount for a reliable connection. You’ll need dedicated crimping tools designed for JST XH pins, not generic pliers. The process involves stripping the wire to the correct length, inserting it into the pin, and using the crimping tool to crimp both the conductor and insulation parts of the pin securely. An improper crimp is a leading cause of connection failure. While it can be done manually, for high volume or critical applications, relying on a reputable JST XH Connector Cables factory or supplier that offers pre-crimped cables or assembly services is highly recommended to ensure consistent quality.

- “Can I use JST XH connectors for high-power LED arrays?”

- For very high-power LED arrays drawing currents significantly above 3A, JST XH connectors may not be the ideal choice. While technically possible to parallel multiple pins to carry more current, this adds complexity and potential points of failure. In such scenarios, it’s better to opt for connectors specifically designed for higher current loads, such as JST VH, Molex Micro-Fit, or other power-rated connectors, which have larger contact areas and higher current capacities.

- “What are the common failure modes of JST XH connectors in LED systems and how can I prevent them?”

- Common failure modes include: poor crimps (leading to high resistance and heat), incorrect mating (pins bent or not fully inserted), excessive force during insertion/removal (damaging housing or pins), and environmental factors (moisture, extreme temperatures, vibration causing intermittent contact). Prevention involves: using correct crimping tools and techniques, ensuring proper alignment during mating, avoiding excessive force, securing cables with strain relief, and protecting connectors from harsh environments.

- “Where can I source reliable JST XH connector cables and components?”

- For optimal quality and authenticity, always source JST XH components from authorized distributors or directly from a reputable JST XH Connector Cables supplier. While generic alternatives exist, genuine JST parts undergo rigorous quality control and adhere to strict manufacturing standards, ensuring long-term reliability and safety, which is crucial for the performance and longevity of your LED products.

5. Best Practices for Designing with JST XH Connectors in LED Systems

Integrating JST XH Connector Cables effectively into your LED lighting designs goes beyond just selecting the right part. Thoughtful design practices can significantly enhance system performance, reliability, and ease of manufacturing.

- Layout and Routing Considerations:

- Minimize wire length: Shorter wires reduce voltage drop and signal degradation, especially important for long LED strips or high-frequency data lines.

- Avoid sharp bends: Ensure cable routing has generous bend radii to prevent stress on wires and terminals, which can lead to fatigue and eventual failure.

- Implement proper strain relief: For cables that will experience movement or tension, use cable ties, clips, or dedicated strain relief features to protect the connector pins from pulling forces. This is particularly important for applications where the JST XH Connector Cables might be frequently handled.

- Thermal Management:

- Consider heat dissipation: Although JST XH connectors have relatively low contact resistance, any current flowing through them will generate some heat. In high-power LED applications, ensure connectors are not placed directly in areas of high heat concentration (e.g., very close to high-power LED chips or heat sinks) to prevent material degradation over time.

- Ventilation: If the connector is enclosed, ensure adequate ventilation to dissipate any heat generated, especially if operating near the upper limits of its current rating.

- Compatibility with LED Drivers and Controllers:

- Verify pinout: Always double-check the pinout configuration of your LED driver or controller against the JST XH connector cable. Mismatched pinouts can lead to system malfunction or even permanent damage to components.

- Voltage and current matching: Ensure the voltage and current capabilities of the connector align with the output of your LED driver and the requirements of your LED load. An experienced JST XH Connector Cables manufacture will often provide custom cable assemblies with correctly matched wire gauges for specific driver outputs.

- Testing and Quality Assurance:

- Continuity testing: After assembly, perform continuity tests on all pins to ensure proper electrical connection and identify any open circuits.

- Pull tests: For critical applications, conduct gentle pull tests on individual crimped wires to verify the mechanical integrity of the crimp.

- Visual inspection: A thorough visual inspection for bent pins, proper crimping, and correct mating is a simple yet effective quality control step.

- Environmental testing: For products destined for demanding environments, consider accelerated life testing or environmental chamber testing to simulate real-world conditions and verify long-term reliability of the JST XH Connector Cables.

6. Conclusion

JST XH Connector Cables are far more than just simple wiring components; they are a fundamental building block in the success of modern LED lighting systems. Their compact size, robust design, and ease of use make them an indispensable choice for designers and manufacturers across the globe. From enabling intricate RGB effects on flexible strips to ensuring reliable power delivery to critical modules, the XH series offers a compelling balance of performance, cost-effectiveness, and design flexibility.As LED technology continues to evolve, pushing boundaries in efficiency and miniaturization, the demand for reliable, high-density interconnections will only grow. The enduring popularity of the JST XH connector speaks volumes about its ability to meet these evolving needs. For anyone involved in LED lighting – whether you’re a product designer, an engineer, or a dedicated hobbyist – a deep understanding of these versatile cables is essential for creating robust, efficient, and long-lasting illumination solutions. Choosing a reputable JST XH Connector Cables factory or supplier ensures the quality and consistency that your LED projects deserve.