The Critical Choice in LED Strip Connections

LED strips have transformed lighting, offering incredible versatility for homes, businesses, and creative projects. But to truly unlock their potential, you need reliable LED Strip Connectors. These often-overlooked components are the unsung heroes that bridge the gaps, extend runs, and allow for intricate designs. Yet, when it comes to solderless options, a common dilemma emerges: which provides the most secure connection—clip-on or wire-to-strip LED Strip Connectors?

This guide will dive deep into these two popular types, comparing their mechanisms, advantages, disadvantages, and ideal use cases. By the end, you’ll have a clear understanding of which connector is best suited for your project’s security and longevity needs, whether you’re dealing with an LED Strip Connectors factory or simply buying a few for a DIY job.

Understanding Clip-on LED Strip Connectors

Clip-on LED Strip Connectors are famous for their simplicity and speed. They represent the ultimate “plug-and-play” solution for connecting LED strips without any soldering.

Mechanism and Design

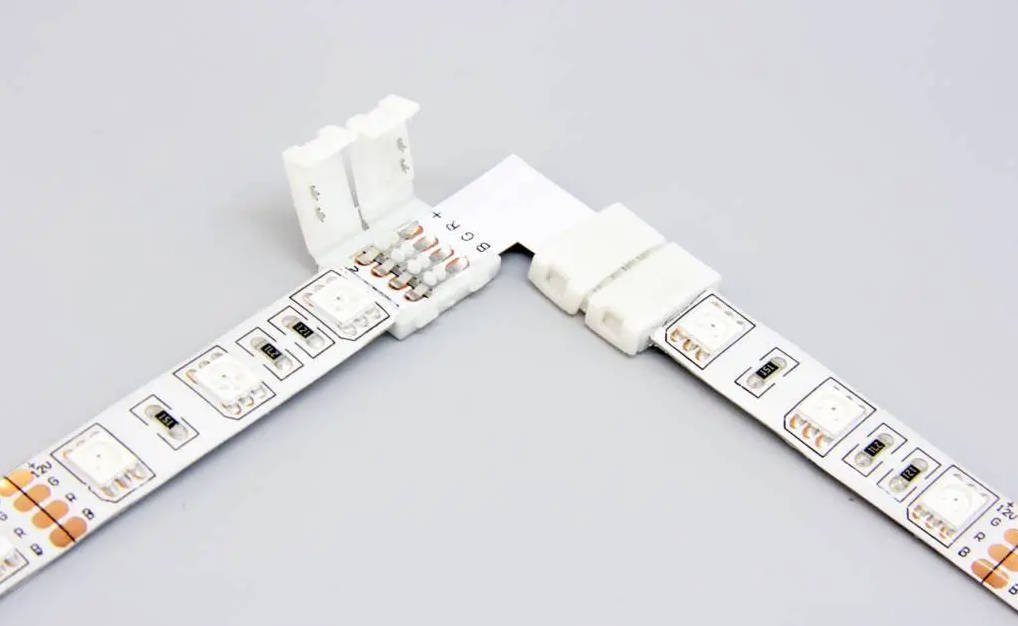

At their core, clip-on connectors work by physically clamping down onto the LED strip’s copper pads, piercing through any protective coating to establish an electrical connection. They often feature small, sharp pins or conductive teeth that make contact with the positive and negative terminals, or the individual color channels (R, G, B, W) on your strip.

You’ll find these connectors in various forms: straight connectors for extending runs, L-shape for clean 90-degree turns, T-shape for splitting circuits, and gapless connectors for an uninterrupted light line.

Advantages (Where Clip-ons Shine)

- Ease of Installation: This is their undisputed strongest suit. You don’t need any specialized tools like soldering irons or even wire strippers. Simply open the clip, slide the LED strip in, and snap it shut. This makes them incredibly appealing for beginners and quick DIY projects.

- Speed: Because of their straightforward mechanism, installing clip-on connectors is remarkably fast. This saves significant time, especially when dealing with multiple connections.

- Accessibility: Their minimal tool requirement makes LED strip installation accessible to almost anyone, regardless of their technical skill level.

Disadvantages (Potential Weaknesses)

While convenient, clip-on connectors do come with potential drawbacks, particularly concerning security and reliability:

- Security Concerns:

- Lack of Grip Strength: Clip-on connectors are inherently more susceptible to disconnection from accidental tugs, vibrations, or general movement. The clamping force might not be strong enough to withstand constant stress, leading to intermittent connections or complete detachment.

- Imperfect Contact: Sometimes, the small pins may not fully penetrate the silicone coating or oxidation on the strip’s copper pads, resulting in a high-resistance connection. This can cause flickering, reduced brightness, or even localized heat buildup.

- Durability: They tend to be less robust over time. Repeated manipulation or exposure to temperature fluctuations can weaken the plastic clips or the internal contact points, leading to failure.

- Compatibility Issues: Not all clip-ons are universally compatible. Factors like the width of your LED strip, the size and spacing of its copper pads, and whether the strip has a silicone coating (like IP65) can affect whether a clip-on connector will make proper contact. Some require removing the silicone for a reliable connection, defeating some of their “solderless” appeal.

Ideal Use Cases for Clip-ons

Given their characteristics, clip-on connectors are best suited for:

- Temporary installations: Holiday lighting, event decor.

- Prototyping: Quick setup and modification for testing circuits.

- Areas with minimal vibration or handling: Cove lighting, behind furniture where connections won’t be disturbed.

- Beginner projects: When ease of use is the top priority and long-term, rugged reliability isn’t critical.

Understanding Wire-to-Strip LED Strip Connectors

Wire-to-strip LED Strip Connectors offer a more robust solderless alternative, providing a stronger mechanical and electrical connection compared to basic clip-ons.

Mechanism and Design

These connectors typically involve two distinct parts: a mechanism for connecting to the LED strip and a terminal block for securing individual wires. The strip side might use a clamping or piercing method, similar to clip-ons, but often with a more secure internal design. The wire side, however, generally employs a screw-down terminal or a lever-locking mechanism (like Wago-style connectors) to firmly hold stripped wires. This direct wire-to-terminal contact significantly improves reliability.

Advantages (Where Wire-to-Strip Excels)

- Enhanced Security: This is where wire-to-strip connectors truly shine. They offer a much stronger mechanical grip on the wires, drastically reducing the risk of pull-out or accidental disconnection. Once the wires are properly secured, they maintain a stable connection, even under moderate vibration or strain.

- Better Electrical Contact: Because wires are stripped and then clamped directly into a terminal, the electrical contact is typically more consistent and robust. This leads to lower resistance and more reliable power delivery, reducing issues like flickering or voltage drop often associated with less secure connections.

- Improved Durability: With their more solid construction and secure wire termination, wire-to-strip connectors are generally more resilient to wear and tear, making them suitable for long-term installations.

- Versatility: They can often accommodate a wider range of wire gauges, providing more flexibility in your wiring choices. An LED Strip Connectors manufacture producing these often designs them for broad applicability.

Disadvantages (Points to Consider)

Despite their advantages in security, wire-to-strip connectors require a bit more effort:

- Installation Complexity: You’ll need basic tools like wire strippers and often a small screwdriver (for screw-down terminals). The process involves stripping the wires, inserting them correctly, and then securing them, which takes more time and precision than a simple clip-on.

- Time Consuming: While still much faster than soldering, the installation process is slower than using basic clip-on connectors due to the additional steps of wire preparation and termination.

- Skill Requirement: A basic understanding of electrical wiring and proper wire stripping techniques is beneficial to ensure a secure and safe connection. Incorrect stripping can lead to loose wires or short circuits.

Ideal Use Cases for Wire-to-Strip

Wire-to-strip connectors are the preferred choice for:

- Permanent installations: Where long-term reliability and stability are crucial (e.g., architectural lighting, kitchen under-cabinet lighting).

- Areas with moderate vibration or handling: Such as in vehicles, RVs, or furniture that might be moved frequently.

- Professional projects: Where consistent performance and robust connections are non-negotiable.

- Installations requiring maximum solderless security: When you want the convenience of solderless but demand superior reliability.

The Verdict: Which Provides the Most Secure Connection?

When the primary concern is the most secure connection in a solderless application, wire-to-strip LED Strip Connectors consistently outperform clip-on types. The fundamental difference lies in how they physically secure the wires and establish electrical contact. Wire-to-strip methods offer a more robust mechanical clamp on the conductor, leading to superior electrical performance and greater resistance to dislodgement.

Here’s a quick comparison:

| Feature | Clip-on Connectors | Wire-to-Strip Connectors |

| Connection Security | Moderate (prone to accidental disconnection) | High (strong physical wire clamping) |

| Electrical Contact | Variable (can be inconsistent) | Consistent (direct wire-to-terminal contact) |

| Ease of Installation | Very High (no tools needed) | Moderate (requires wire stripping, screwdriver) |

| Installation Speed | Very Fast | Moderate |

| Durability | Moderate (less robust over time) | High (more resilient to wear/vibration) |

| Cost | Generally Lower | Slightly Higher |

| Best For | Temporary, prototyping, low-stress areas | Permanent, reliable, moderate-stress areas |

While clip-on connectors offer unmatched convenience for quick, low-stress applications, their vulnerability to disconnection makes them less ideal for situations where reliability is paramount. If your LED strip installation will be subject to any movement, vibration, or needs to perform reliably for years, investing a little extra time and using wire-to-strip LED Strip Connectors will pay dividends in stability and peace of mind.

Best Practices for Maximizing Connection Security (Regardless of Type)

No matter which LED Strip Connectors you choose, adhering to best practices will significantly improve connection security and longevity:

- Proper Strip Preparation: Always cut LED strips accurately along the designated cut lines. Ensure the copper pads are clean and free from debris or oxidation. For IP-rated strips, carefully peel back or cut away the silicone over the connection points if necessary, as per the connector’s instructions.

- Secure Seating: Whether it’s a clip-on or wire-to-strip, ensure the LED strip or stripped wire is fully and correctly inserted into the connector. For wire-to-strip, double-check that no stray wire strands are exposed, which could cause a short.

- Strain Relief: Never leave connectors dangling or supporting the weight of the LED strip or its wires. Always provide adequate strain relief by securing the LED strip itself close to the connector using adhesive, clips, or channels. This prevents tension on the connection points.

- Environmental Considerations: For damp or outdoor environments, ensure both your LED strip and your chosen LED Strip Connectors are appropriately IP-rated. For wire-to-strip connections, consider using heat shrink tubing or waterproof junction boxes for added protection.

- Quality Matters: Not all connectors are created equal. Sourcing your LED Strip Connectors from a reputable LED Strip Connectors factory or LED Strip Connectors manufacture can make a significant difference in connection quality, material durability, and overall reliability. Cheap, poorly made connectors are a common source of LED strip failures.

Conclusion: Making an Informed Connection

The choice between clip-on and wire-to-strip LED Strip Connectors boils down to balancing ease of installation with the required level of connection security and long-term reliability. For quick tests or applications where the strip won’t be disturbed, clip-ons are undeniably convenient. However, for any installation where durability, consistent performance, and unwavering stability are crucial, wire-to-strip connectors offer a superior and more secure connection. By understanding these differences and following best practices, you can make informed decisions that ensure your LED lighting projects shine brightly and reliably for years to come.