Switching from fluorescent tubes to LED lighting is one of the smartest upgrades you can make for your home or business. Compared to traditional fluorescent tubes, LED lights offer superior energy efficiency, a longer lifespan, and better light quality. Plus, the replacement process is faster and easier than ever!

There are many ways to convert fluorescent tubes to LEDs, ranging from simple plug-and-play replacements to complete fixture upgrades. You can choose the right solution based on your specific needs and budget.

Read on to explore the top conversion options to help you choose the best solution for your facility.

Why Switch from Fluorescent Tubes to LEDs?

Replacing fluorescent tubes with LEDs is a wise move that saves costs while ensuring better lighting. Here are some key reasons to make the switch:

- Energy Efficiency: LED lights are up to 75% more energy-efficient than fluorescent tubes, significantly lowering electricity bills.

- Longer Lifespan: LEDs can last 50,000 hours or more, compared to just 15,000 hours for fluorescents. This means lower replacement costs and less maintenance.

- Better Light Quality: LEDs provide stable, flicker-free light with better color rendering (CRI), creating a more comfortable environment.

- Durability and Reliability: LEDs are robust and can withstand shocks, vibrations, and extreme temperatures, making them ideal for commercial and industrial use.

- Less Heat Emission: Fluorescents waste 75-80% of energy as heat, whereas LEDs convert 80-90% of energy into light, keeping indoor temperatures lower and reducing cooling costs.

Top 5 Best Options to Convert Fluorescent Tubes to LEDs

Here are the 5 most effective methods to upgrade your lighting:

1. Direct Replacement LED Tubes (Type A / Plug-and-Play)

Type A tubes, or “Plug-and-Play” tubes, are the easiest DIY option. They are designed to work with your existing electronic ballast.

- How it works: Simply remove the old fluorescent tube and snap in the new LED tube. No rewiring is needed.

- Pros: Quick and easy installation; low labor costs; great for offices and retail stores.

- Cons: Compatibility issues with some ballasts; if the ballast fails, the light won’t work.

2. Hybrid LED Tubes (Type A + B)

Hybrid tubes offer maximum flexibility. They can work with the existing ballast (Plug-and-Play) or operate directly on line voltage (Ballast Bypass).

- How it works: Install them as a direct replacement initially. If the ballast fails later, you can rewire the fixture to bypass the ballast and keep using the same tube.

- Pros: Versatile installation; minimizes downtime; works with both magnetic and electronic ballasts.

- Cons: Higher upfront cost compared to single-mode tubes; rewiring requires electrical knowledge.

3. Ballast Bypass LED Tubes (Type B / Direct Wire)

Type B tubes bypass the ballast entirely and run directly on mains voltage. This is a favorite among professional electricians.

- How it works: The ballast is removed or disconnected, and the fixture is rewired to provide power directly to the sockets.

- Pros: Eliminates ballast maintenance and failure points; higher efficiency; prevents flickering.

- Cons: Requires electrical rewiring; installation takes longer and may need a qualified electrician.

4. LED Retrofit Kits

Retrofit kits are designed to upgrade the internal components of your existing fixture without replacing the housing.

- How it works: You remove the fluorescent tubes and ballast, then install new LED modules and drivers into the existing fixture body using magnets or screws.

- Pros: Keeps the original fixture look; reduces waste; provides high-quality, integrated LED lighting.

- Cons: Installation is more involved than changing a tube; requires a skilled technician.

5. Replace the Entire Fixture

The final option is to remove the old fluorescent fixture completely and install a brand-new LED fixture.

- How it works: Take down the old unit and mount a modern “Smart” LED fixture.

- Pros: Maximum energy savings; access to modern features like dimming, sensors, and remote control; creates a fresh look.

- Cons: Highest upfront cost; labor-intensive installation.

LED Tube Sizes and Conversion Guide

- T8 Tubes (1-inch diameter): The most common option for offices, schools, and hospitals. They offer a great balance of brightness and efficiency (90-120 lm/W) with various color temperatures (2700K to 6500K).

- T5 Tubes (5/8-inch diameter): Slimmer and more efficient than T8s. ideal for task lighting, under-cabinet lighting, and spaces needing high brightness (up to 130 lm/W).

- T12 Tubes (1.5-inch diameter): Older, thicker tubes with lower efficiency (50-70 lm/W). They are prone to flickering and higher maintenance. Replacing these with LEDs brings massive energy savings.

Other LED Alternatives

Beyond tube lights, you can also consider:

- LED Panel Lights: Flat, slim panels perfect for drop ceilings in offices.

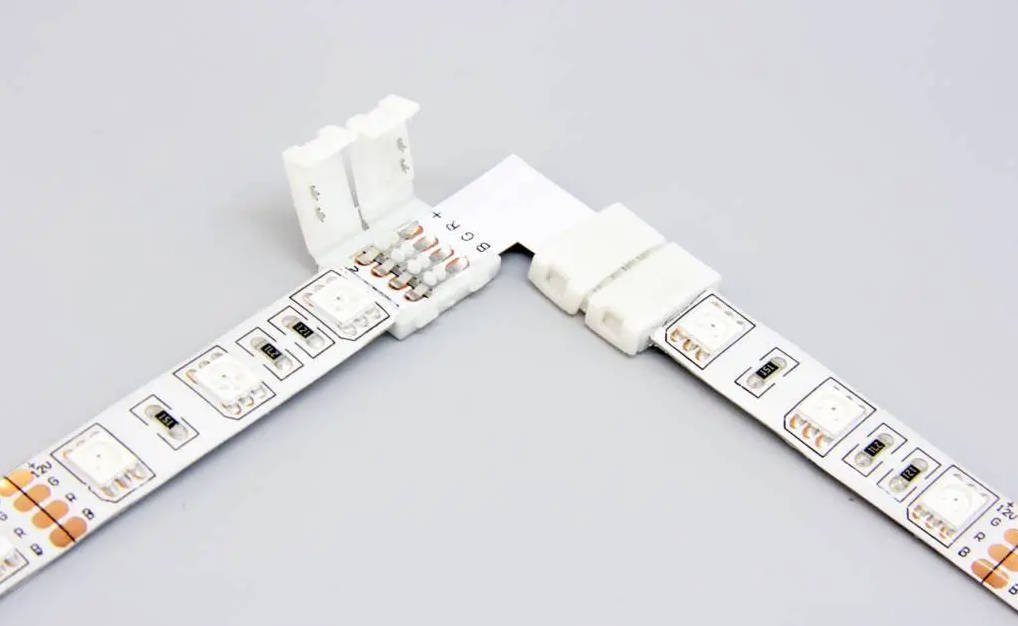

- LED Strip Lights: Flexible strips for accent or under-cabinet lighting.

Conclusion

Converting to LED is a long-term investment that pays off through lower energy bills and reduced maintenance. Whether you choose a simple Type A replacement for convenience or a Type B bypass for maximum efficiency, there is a solution to fit every need.