Introduction

Outdoor lighting is an integral part of architectural design, landscaping, and safety. However, outdoor LED strip lighting comes with its own set of challenges. To ensure the longevity and reliability of your outdoor lighting installations, it is crucial to address the vulnerability of LED strip light connectors to moisture and water. In this article, we will explore the various aspects of waterproofing LED strip light connectors, providing valuable insights for users, whether you’re an individual, a contractor, or a business owner.

Understanding the Need for Waterproofing

Outdoor lighting systems face harsh environmental conditions. Rain, snow, humidity, and temperature fluctuations are just a few of the challenges that can compromise the integrity of your lighting setup. Among the most vulnerable components are the LED strip light connectors that link the LED strips together.

Moisture and water exposure can lead to several issues:

- Corrosion: Over time, connectors may corrode, impacting electrical conductivity.

- Short Circuits: Water infiltration can cause short circuits, leading to potential safety hazards.

- Diminished Lifespan: Unprotected connectors may not last as long as their waterproofed counterparts.

Addressing these concerns is vital to maintaining the performance of your outdoor LED strip lighting.

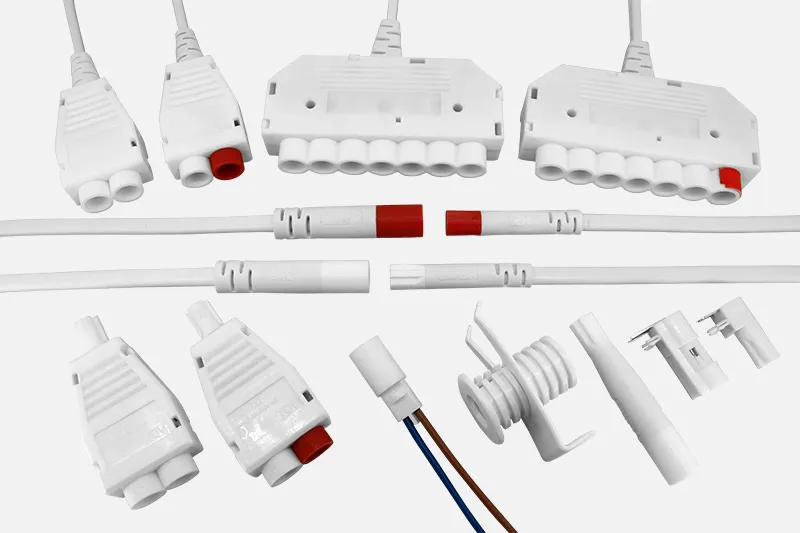

Types of LED Strip Light Connectors

When it comes to LED strip light connectors, it’s essential to choose the right type for your outdoor lighting project. These connectors come in various forms, and their suitability for outdoor use can vary. Some connectors are better designed to resist moisture and provide a more secure connection. It’s essential to consider the pros and cons of each type, taking into account the environmental conditions your lighting system will face.

For users seeking LED strip light connectors, it’s essential to work with reputable manufacturers and suppliers. The quality of the connectors and their suitability for outdoor use often depends on the source. Be sure to inquire about the connectors’ IP (Ingress Protection) ratings, which indicate their resistance to dust and water.

Waterproofing Methods and Solutions

Waterproofing your LED strip light connectors is a crucial step in ensuring the longevity and reliability of your outdoor lighting system. There are various methods and solutions available to protect your connectors from moisture and water damage. Here are some of the most common approaches:

- Heat Shrink Tubing: Heat shrink tubing is an effective method that involves applying a heat-sensitive material to the connectors, shrinks and seals tightly when heated. This creates a barrier that prevents water infiltration.

- Waterproof Connector Caps: Some connectors have dedicated waterproof caps or covers that provide a protective barrier against moisture. These caps are designed to fit the connectors snugly.

- Silicone Sealant: Applying a waterproof silicone sealant around the connectors can create a tight seal. Silicone is flexible and resistant to moisture, making it a popular choice for outdoor applications.

- Waterproof Junction Boxes: Using waterproof junction boxes to encase the connectors can be a comprehensive solution. These boxes keep connectors dry and secure in various outdoor conditions.

The choice of waterproofing method may depend on the LED strip light connectors you are using and the specific environmental conditions they will face. When seeking LED strip light connectors, consider discussing waterproofing options with the manufacturers and suppliers to ensure compatibility.

Selecting the Right Waterproofing Solution

Selecting the appropriate waterproofing solution for your LED strip light connectors is a critical decision that can significantly impact the performance and lifespan of your outdoor lighting system. When making this choice, consider the following factors:

- Environmental Conditions: Assess the specific ecological conditions your outdoor lighting will face. Consider factors such as humidity levels, exposure to rain or snow, and temperature fluctuations. Some areas may require more robust waterproofing solutions than others.

- Connector Type: Different types of LED strip light connectors may have specific recommendations for waterproofing. Consult with the manufacturer or supplier to ensure compatibility between the connector type and the chosen waterproofing method.

- IP Rating: Check the IP (Ingress Protection) rating of the connectors and the selected waterproofing method. IP ratings indicate the level of protection against dust and water. Match the IP rating of the connectors with that of the chosen waterproofing solution.

- Installation Ease: Consider the practicality of applying the waterproofing method. Some methods, like heat shrink tubing, maybe more accessible for DIY installations, while others, like waterproof junction boxes, might require professional expertise.

- Cost and Longevity: Evaluate the cost of the waterproofing method and the expected longevity it provides. Sometimes, investing in a more robust waterproofing solution upfront can save you money in the long run by preventing costly damage and replacements.

Considering these factors, you can make an informed decision regarding safeguarding your LED strip light connectors against the outdoor elements. The following section will provide you with a step-by-step guide on how to apply the selected waterproofing solution effectively.

Step-by-Step Guide to Waterproofing

Waterproofing your LED strip light connectors is a systematic process that, when done correctly, ensures the protection of your outdoor lighting system. Here is a step-by-step guide to help you through the process:

Step 1: Gather Materials

Before you begin, ensure you have all the necessary materials, including the waterproofing method of your choice, connectors, sealants, and any tools required for the application.

Step 2: Inspect Connectors

Examine the connectors to ensure they are clean and in good condition. Any existing damage should be addressed before waterproofing.

Step 3: Apply Waterproofing

Depending on your chosen method, carefully apply the waterproofing solution to the connectors. Follow the manufacturer’s instructions for your specific solution. Make sure the application is uniform and covers all vulnerable areas.

Step 4: Allow for Drying or Curing

If your chosen waterproofing solution requires drying or curing time, be patient and allow it to set completely. This step is crucial to ensure a watertight seal.

Step 5: Check Seals

Inspect the sealed connectors for any gaps or imperfections. If you find any, reapply the waterproofing material as needed. A thorough seal is essential for protection.

Step 6: Test the Waterproofing

Before installing the connectors in your outdoor lighting system, perform a test to ensure the waterproofing is effective. You can use a water spray or submerge the connectors briefly to check for any leaks.

By following these steps diligently, you can significantly reduce the risk of moisture and water damage to your LED strip light connectors in outdoor lighting installations. This systematic approach ensures the reliability and longevity of your system.

Testing and Quality Assurance

Ensuring the effectiveness of your waterproofing efforts is crucial to maintaining the long-term performance and reliability of your outdoor lighting system. Here, we will discuss the importance of testing and quality assurance.

Testing Methods:

- Water Spray Test: This involves spraying water on the connectors to simulate rain or exposure to moisture. Check for any signs of water infiltration or leakage.

- Submersion Test: Submerge the connectors in water, if possible, and observe for any water ingress. This test is beneficial for connectors exposed to constant moisture.

- Thermal Cycling Test: Subject the connectors to temperature fluctuations to ensure the waterproofing material remains intact under varying conditions.

- Visual Inspection: Regularly inspect the connectors for any signs of wear, damage, or peeling of the waterproofing material.

Quality Assurance:

- Use High-Quality Materials: Ensure that the materials you use for waterproofing are high quality and compatible with your connectors.

- Follow Manufacturer Recommendations: Adhere to the manufacturer’s guidelines for the connectors and the chosen waterproofing method.

- Regular Maintenance: Implement a maintenance schedule to check and reapply waterproofing as needed. Over time, the effectiveness of the seal can diminish.

- Replacement of Damaged Connectors: If you notice any damaged connectors or waterproofing, promptly replace or repair them to prevent further issues.

By conducting regular tests and maintaining a quality assurance regimen, you can proactively address potential vulnerabilities in your LED strip light connectors. This ensures that your outdoor lighting system remains reliable and durable over time.

Maintenance and Longevity

To ensure the continued reliability and performance of your outdoor LED strip lighting system, regular maintenance is essential. Here are some maintenance strategies to extend the longevity of your LED strip light connectors:

- Routine Inspections: Regularly inspect the connectors for signs of wear, damage, or peeling of the waterproofing material. Catching issues early can prevent more significant problems.

- Cleaning: Keep the connectors and surrounding areas clean from dirt and debris. A clean environment reduces the chances of moisture penetration.

- Reapplication of Waterproofing: Over time, the effectiveness of the waterproofing material may diminish. Plan to reapply the waterproofing solution as needed to maintain a strong seal.

- Protection from Physical Damage: Ensure the connectors are adequately protected from physical damage, such as impacts, crushing, or bending.

- Temperature Control: If possible, regulate the temperature of the installation area. Extreme temperature fluctuations can affect the waterproofing material over time.

- Proper Wiring and Installation: Ensure that the connectors are correctly wired and installed to minimize connection stress.

By implementing these maintenance strategies, you can extend the longevity of your LED strip light connectors and reduce the risk of performance issues. Regular upkeep is an investment in the long-term success of your outdoor lighting system.

Case Studies and Real-world Examples

Real-world examples help to underline the significance of waterproofing LED strip light connectors in outdoor lighting installations. Here are a few case studies that showcase the impact of effective waterproofing:

Case Study 1: Architectural Lighting Design

Scenario: An architectural firm was tasked with illuminating a landmark building with outdoor LED strip lighting. During the initial installation, standard connectors were used without proper waterproofing.

Outcome: The connectors were exposed to heavy rainfall, and within a few months, multiple connectors failed due to water infiltration. This led to disruptions in the lighting scheme and costly repairs.

Solution: The firm re-evaluated the connectors, replaced them with waterproof versions, and implemented a routine maintenance schedule. This resolved the issues and improved the overall reliability of the lighting system.

Case Study 2: Landscape Lighting

Scenario: A landscaping company installed LED strip lighting to highlight a large garden area. They initially used connectors without considering the waterproofing requirements.

Outcome: After a season of exposure to outdoor conditions, the connectors corroded and showed signs of short circuits, causing sections of the garden to go dark.

Solution: The company switched to waterproofed connectors and implemented a robust maintenance program. This not only fixed the issues but also enhanced the garden’s aesthetic appeal.

These case studies emphasize the importance of proper waterproofing methods and high-quality LED strip light connectors in outdoor lighting applications. The performance and longevity of the lighting system greatly depend on the initial choices made.

Conclusion

In conclusion, waterproofing LED strip light connectors for outdoor lighting is a critical step in ensuring the reliability and longevity of your lighting system. Consider the environmental conditions, connector types, and quality of materials when making your choices. Implementing the proper waterproofing methods and maintaining your connectors properly can prevent issues and lead to a successful outdoor lighting installation.

By following the guidance provided in this article and learning from real-world examples, you can make informed decisions when it comes to waterproofing your connectors and enjoy the benefits of a well-illuminated and trouble-free outdoor space.

If you have further questions or require additional information, consult with reputable LED strip light connector manufacturers and suppliers to ensure the success of your outdoor lighting project.