Service

We Provide The

OEM & ODM Service

We provide ODM & OEM service, with help of 16 years' experience in design, tooling and test, we got the ability to quickly develop excellent products to work with LED light, driver and sensor.

30% of our business comes from customization. The options includes appearance design, functions, LOGO on products, product modifications and package.

10 expert R&D team focus on development trend of lighting lamps and lanterns for years, timely develop new connectors in accordance with market demands. With long-term and stable cooperation with mould manufacturer, we can fast open mould match up with customer brand marketing and cost request.

Requirement Gathering

We works with the customers to gather requirements for the LED wiring connector system(Connectors, distribution box, PCB connectors etc.), including the desired features, specifications, and performance criteria.

Design

Our engineer designs the LED wiring connector system based on the requirements provided by the customers. This may involve creating initial design concepts, selecting materials, and developing a prototype.

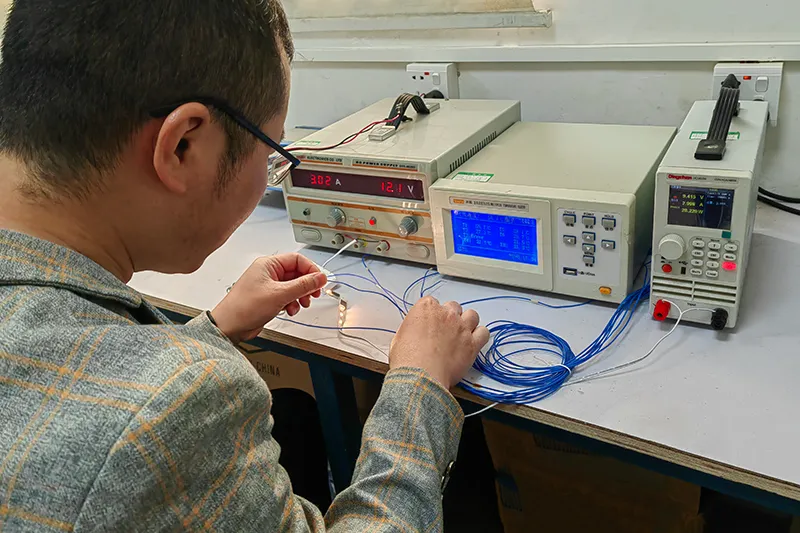

Prototype Testing

We tests the prototype to ensure that it meets the customer's requirements and performs as expected. This may involve various types of testing, such as mechanical testing, electrical testing, and environmental testing.

Production Planning

Once the prototype has been approved by the customer, We develops a production plan for the LED wiring connector system. This may involve selecting suppliers for materials and components, developing manufacturing processes, and creating a production schedule.

Manufacturing

After our customers place orders to us , we produces the LED wiring connector system according to the production plan. This may involve various types of manufacturing processes, such as cable cutting, terminals cramping , injection molding, stamping, and assembly.

Quality Control

Throughout the manufacturing process, we performs quality control checks to ensure that the LED wiring connector system meets the customer's requirements and performs as expected. This may involve various types of quality control measures, such as visual inspection, functional testing, and statistical process control.

Delivery

Once the LED wiring connector system has been manufactured and has passed all quality control checks, it is delivered to the customer. We may also provide after-sales support and maintenance for the LED wiring connector system, as needed.