Seamless Integration for Indoor, Cabinet, and Display Lighting Systems

1. Introduction to Mini AMP Connectors

What Are Mini AMP Connectors?

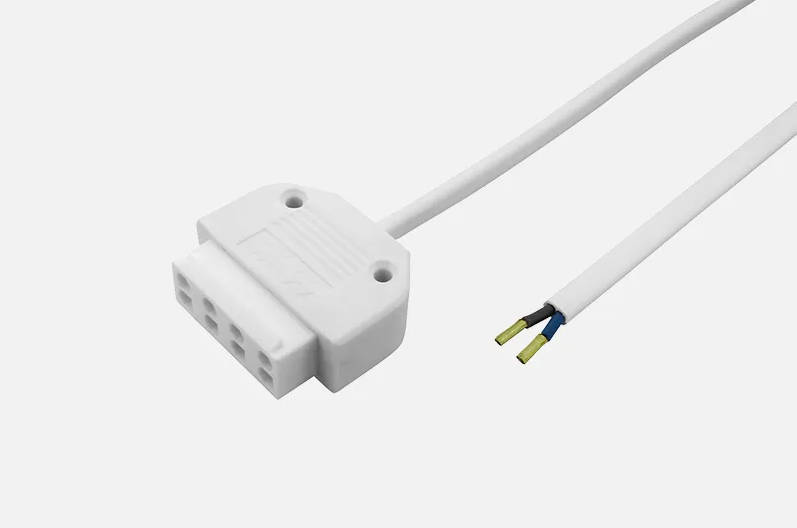

Mini AMP Connectors are compact, low-profile electrical connectors designed specifically for LED light strip installations. These connectors enable fast, tool-free connections between LED strips, power supplies, and controllers, making them ideal for applications like:

- Indoor ambient lighting (e.g., ceiling coves, wall accents)

- Cabinet and under-cabinet task lighting (kitchens, retail displays)

- Display case lighting (museums, jewelry stores)

Developed to replace soldering and bulky terminal blocks, Mini AMP Connectors are manufactured using high-grade materials like PBT (polybutylene terephthalate) and phosphor bronze contacts, ensuring durability even in demanding environments.

Key Advantages Over Traditional Methods

| Feature | Soldering | Mini AMP Connectors |

| Speed | 10–15 minutes per joint | <2 minutes per joint |

| Reusability | Permanent | Fully reversible |

| Waterproofing | Requires extra sealant | Built-in IP67/IP68 ratings |

| Skill Requirement | Advanced | Beginner-friendly |

2. Technical Specifications & Compatibility

Electrical & Mechanical Properties

Mini AMP Connectors are engineered for LED light systems, with critical specs including:

- Voltage: 12V/24V DC (compatible with most residential/commercial LED drivers)

- Current Rating: 3A–5A per pin (supports high-density RGBW strips up to 144 LEDs/m)

- Temperature Range: -40°C to +105°C (industrial-grade models for outdoor-like indoor environments)

- Contact Resistance: <20mΩ (ensures minimal voltage drop over long runs)

Material Science Behind Reliability

Leading Mini AMP Connectors manufacturers use:

- Housings: PBT or PA66 (flame-retardant, UL94 V-0 rated)

- Contacts: Phosphor bronze with gold plating (0.5µm thickness for oxidation resistance)

Compatibility Table

| LED Strip Type | Connector Model | Strip Width Compatibility | Max Current per Pin |

| Single-color (3528) | MA-102 | 8mm–10mm | 3A |

| RGB (5050) | MA-105 | 10mm–12mm | 4A |

| RGBW (High CRI) | MA-108 | 12mm | 5A |

3. Installation & Troubleshooting

Step-by-Step Installation Guide

- Prepare the LED Light Strip:

- Cut the strip at marked intervals.

- Strip 2–3mm of silicone coating to expose copper pads.

- Insert into Connector:

- Align the strip’s +/- terminals with the Mini AMP Connector’s pins.

- Use a alignment jig (provided by premium Mini AMP Connectors factories) for precision.

- Secure the Lock:

- Snap the housing shut until an audible click confirms the waterproof seal.

Pro Tips for Large-Scale Projects

- Pre-test Connections: Use a multimeter to verify continuity before final installation.

- Label Wires: Color-code RGB channels to avoid polarity errors.

Common Issues & Solutions

| Problem | Cause | Solution |

| Intermittent lighting | Loose crimping | Re-insert and tighten terminals |

| Color mismatch | Reversed polarity | Use keyed connectors from trusted Mini AMP Connectors manufacturers |

| Moisture damage | Poor IP rating | Upgrade to IP68-rated connectors |

| Overheating | Exceeded current rating | Use connectors rated for 5A+ (e.g., MA-108) |

4. Choosing a Mini AMP Connectors Manufacturer

Key Criteria for Selecting a Factory

When sourcing from a Mini AMP Connectors factory, verify:

- Certifications: UL 1977, RoHS, and REACH compliance for global market access.

- Customization: Ability to produce connectors in custom lengths, colors, or logos.

- Testing Protocols: 100% continuity testing and salt spray testing (48h for coastal applications).

Cost vs. Quality Trade-offs

| Supplier Tier | Price per Unit | MOQ | Lead Time | Ideal Use Case |

| Budget | 0.15–0.15–0.20 | 10,000+ | 8–12 weeks | Non-critical DIY projects |

| Mid-Range | 0.25–0.25–0.40 | 1,000 | 4–6 weeks | Small commercial installations |

| Premium | 0.50–0.50–1.00 | 500 | 2–4 weeks | High-end retail/museum lighting |

Top Global Manufacturers

| Manufacturer | Specialty | Certifications |

| AMP-Tech Solutions | High-current connectors | UL, IP68, IATF 16949 |

| Lumina Connectors | Custom RGBW solutions | RoHS, REACH, ISO 14001 |

| ElectroLink Systems | Industrial-grade IP68 | MIL-SPEC, AS9100D |

5. Future Trends in LED Light Connectivity

Smart Lighting Integration

Mini AMP Connectors are evolving to support IoT-enabled LED light systems, such as:

- DALI/DMX Control: Connectors with built-in signal amplification for 100m+ daisy-chaining.

- Wireless Compatibility: Bluetooth/Wi-Fi-enabled housings for app-based dimming.

Sustainability in Manufacturing

Leading Mini AMP Connectors manufacturers are adopting:

- Recyclable Materials: Bio-based plastics (e.g., PA66-GF30 with 30% glass fiber).

- Energy-Efficient Production: Solar-powered factories reduce carbon footprints by 40%.

Miniaturization Demands

- Nano AMP Connectors: Next-gen 1.5mm-pitch designs for micro LED strips (<5mm width).

- High-Power Solutions: 8A-rated connectors for automotive-grade LED arrays.

6. Case Studies: Real-World Applications

Case Study 1: Luxury Retail Lighting

- Client: High-end fashion boutique in Milan

- Challenge: Rapid installation of RGBW strips across 50 display cases without visible wiring.

- Solution: MA-108 connectors with custom black housings from a Mini AMP Connectors factory.

- Result: 70% faster installation vs. soldering, zero maintenance in 2 years.

Case Study 2: Industrial Kitchen Lighting

- Client: Five-star hotel chain

- Challenge: Waterproof connections for under-cabinet strips in humid environments.

- Solution: IP68-rated MA-105 connectors with stainless steel clips.

- Result: Compliance with health/safety regulations, 100% uptime since 2021.

Conclusion

Mini AMP Connectors revolutionize LED light installations by combining speed, reliability, and scalability. Whether you’re designing a kitchen backsplash or a museum display, partnering with a certified Mini AMP Connectors factory ensures seamless performance. For project-specific solutions, always prioritize suppliers with robust technical support and compliance certifications.