Unplugging the Mystery of LED Strip Plugs

Choosing the right LED Strip Plugs is far more critical than many realize. These seemingly small components are the lynchpin of any successful LED lighting installation, directly impacting performance, safety, and the longevity of your strips. Get it wrong, and you could face flickering lights, short circuits, or even fire hazards. Get it right, and you unlock vibrant, reliable illumination that enhances any space.

This comprehensive guide will demystify the various types of LED Strip Plugs, focusing on DC, RGB/RGBW, and waterproof options. We’ll dive into their specific uses, crucial considerations for selection, and address common questions to help you make informed decisions, whether you’re a DIY enthusiast or a professional working with an LED Strip Plugs factory or an LED Strip Connectors manufacture.

The Power Connection: DC Barrel Jack Plugs

The most fundamental type of LED strip plug is the DC Barrel Jack Plug. These are primarily used to supply power to single-color LED strips or as the input for LED controllers.

Anatomy of a DC Barrel Jack Plug

A DC barrel jack plug consists of a central pin and an outer sleeve. The most common sizes you’ll encounter are 2.1mm x 5.5mm or 2.5mm x 5.5mm, where the first number indicates the diameter of the central pin and the second is the outer diameter of the barrel. Compatibility is paramount here; a mismatch, even slight, will result in a loose connection or no connection at all.

| Specification | Description | Common Sizes | Polarity |

| Pin Diameter | Inner pin size | 2.1mm, 2.5mm | Center Positive (standard) |

| Outer Diameter | Barrel size | 5.5mm | N/A |

Crucially, DC barrel jack plugs almost universally operate on a “center positive” polarity. This means the central pin carries the positive voltage, and the outer barrel is negative (ground). Reversing polarity can instantly damage your LED strip or controller, so always double-check your power supply’s output before connecting.

Common Applications

- Connecting single-color LED strips directly to a power supply.

- Providing power input to LED dimmers or basic single-channel controllers.

- Powering various low-voltage electronic devices.

Key Considerations for Users

When selecting DC barrel jack plugs, always:

- Match voltage and current ratings: Ensure the plug can safely handle the voltage and current required by your LED strip and power supply. Overloading can lead to overheating.

- Verify physical fit: The barrel size must precisely match the jack on your LED strip or device.

- Prioritize secure connections: A wobbly connection can cause flickering or intermittent power, reducing the lifespan of your setup.

The Color & Control Connection: RGB and RGBW Plugs

When your LED strips transcend single-color illumination to offer a spectrum of hues, you’ll enter the realm of RGB and RGBW Plugs. These specialized LED Strip Connectors transmit not just power but also control signals for color manipulation.

RGB 4-Pin Plugs

RGB 4-Pin Plugs are standard for conventional color-changing LED strips. They typically feature four pins with a common pinout: R (Red), G (Green), B (Blue), and V+ (Common Positive).

- Pinout Explanation: Each R, G, and B pin controls the intensity of its respective color. By varying the power to these pins, millions of colors can be created. The V+ (or +12V/24V) pin provides the constant positive voltage.

- Common Anode vs. Common Cathode: The vast majority of 12V or 24V LED strips use a common anode configuration, meaning the V+ line is shared positive, and the individual color channels are switched to ground. Ensure your controller matches this configuration.

- Applications: Standard RGB (Red, Green, Blue) LED strips for mood lighting, accent lighting, and decorative purposes.

RGBW/RGBWW 5-Pin Plugs (and Beyond)

As lighting technology evolves, so do the connectors. RGBW 5-Pin Plugs (and RGBWW for tunable white) add a dedicated white channel.

- Pinout Explanation: In addition to R, G, B, and V+, there’s a dedicated ‘W’ (White) pin. This allows for a purer, brighter white light than mixing RGB colors, or even adjustable white temperatures (warm white and cool white) with RGBWW.

- Applications: Premium LED strips requiring true white light alongside color, often found in professional installations or spaces where both ambiance and task lighting are needed.

- Beyond 5-Pins: For more advanced addressable LED strips (like WS2812B or SK6812), you’ll often find connectors with more than 5 pins, typically employing data lines (like DAT, CLK) and requiring specialized controllers. These often use JST connectors or custom terminal blocks rather than standard ‘plugs.’

Key Considerations for Users

- Match Pin Count and Assignment: The number of pins on your plug must perfectly match your LED strip and controller. Incorrect pin assignment can lead to wrong colors or damage.

- Controller Compatibility: Ensure your controller is designed to work with your specific RGB/RGBW strip type (e.g., common anode).

- Correct Orientation: Always verify the plug’s orientation before insertion. Many plugs are keyed, but forcing them can bend pins or damage the strip.

The Environmental Shield: Waterproof Options

For installations in challenging environments, waterproof LED Strip Plugs are indispensable. They provide a crucial barrier against moisture, dust, and other damaging elements.

Why Waterproofing Matters

Exposure to moisture can cause short circuits, corrosion, and irreversible damage to your LED strips, drastically shortening their lifespan. Dust and debris can also impede heat dissipation, leading to premature failure. Waterproof plugs are essential for outdoor lighting, bathroom vanity lighting, kitchen under-cabinet lighting, marine applications, and any area prone to humidity or splashing.

Types of Waterproof Plugs

- IP-Rated Connectors: These are the gold standard for environmental protection. IP ratings (Ingress Protection) indicate a connector’s resistance to solids and liquids.

- IP65: Dust tight, protected against low-pressure water jets from any direction.

- IP67: Dust tight, protected against immersion in water up to 1 meter for 30 minutes.

- IP68: Dust tight, protected against continuous immersion in water beyond 1 meter. The higher the numbers, the better the protection.

- Screw-on/Compression Fit Plugs: These plugs use a threaded collar or compression mechanism to create a tight seal around the cable and mating connector, often incorporating O-rings for enhanced sealing.

- Overmolded Connectors: These are factory-sealed units where the plug is molded directly onto the cable, offering superior long-term reliability and water resistance. An LED Strip Connectors manufacture specializing in robust solutions often uses this method.

Key Considerations for Users

- Match IP Rating to Environment: Don’t use an IP65 plug where an IP67 or IP68 is required. Assess the exposure level (splashing, rain, submersion) before selecting.

- Ensure Proper Sealing: For screw-on types, ensure the cap is fully tightened. Using dielectric grease on the contacts can further enhance protection and prevent corrosion in damp environments.

- “Waterproof” Applies to the Connection: Remember that the plug’s waterproof rating only applies to the connection itself. Your LED strip and any other components (like power supplies or controllers) must also be rated for the environment.

Beyond the Basics: Other Important Considerations

Solderless vs. Soldered Plugs

When connecting your LED strips to plugs, you generally have two primary options:

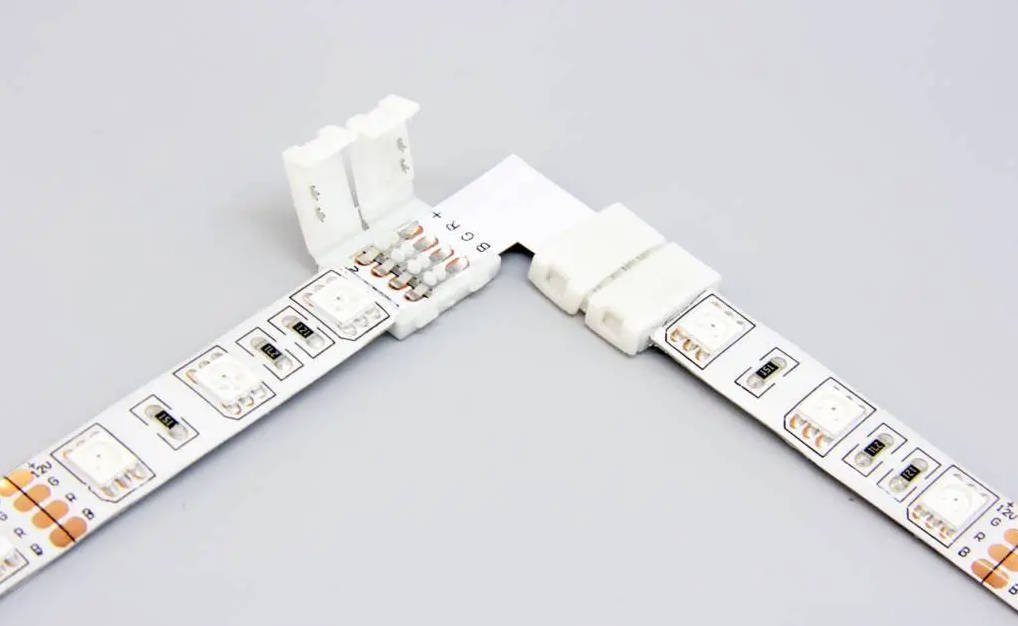

- Solderless (Clip-on) Plugs:

- Pros: Incredibly easy to use, require no specialized tools (like soldering irons), and are quick to install. Ideal for beginners and temporary setups.

- Cons: Can be less secure over time, especially with movement or vibration. They may also introduce slightly higher resistance, potentially causing minor voltage drop over long runs, particularly for a LED Strip Connectors manufacture looking for optimal performance.

- Soldered Plugs:

- Pros: Offer the most secure and reliable connection, with minimal resistance. This ensures consistent power delivery and longevity. Essential for permanent installations and high-power applications.

- Cons: Requires basic soldering skills and equipment. It’s more time-consuming to install.

Current Capacity and Wire Gauge

Never overlook the current capacity of your LED Strip Plugs. Each plug has a maximum current rating. If your LED strip draws more current than the plug is rated for, the plug can overheat, melt, or even cause a fire. Similarly, ensure the wire gauge connected to the plug is adequate for the current it will carry. For instance, an LED Strip Plugs factory designs plugs with specific wire sizes in mind for optimal performance and safety.

Compatibility & Proprietary Systems

While many LED Strip Connectors adhere to industry standards (like common DC barrel sizes or 4/5-pin RGB headers), some manufacturers use proprietary plug designs. This can limit your flexibility when mixing and matching components from different brands. Whenever possible, opt for standard connectors for greater versatility in your LED lighting projects.

Conclusion: Plugging into Success

Understanding the nuances of LED Strip Plugs – from their basic power delivery to their role in color control and environmental protection – is vital for anyone working with LED lighting. By carefully considering DC, RGB/RGBW, and waterproof options, as well as factors like soldering preferences, current capacity, and compatibility, you can ensure a safe, efficient, and visually stunning LED installation. Whether you’re sourcing from an LED Strip Plugs factory or just buying a single connector, making an informed choice will literally light up your world.