Introduction to LED Strip Connectors

LED strip connectors are vital components for creating functional and visually appealing LED lighting systems. These small devices connect LED strips to power sources, controllers, or additional strips, enabling customized lighting for applications ranging from home decor to commercial displays. Whether you’re illuminating a kitchen counter or designing an outdoor lighting feature, the right connector ensures a secure and efficient connection.

Choosing the right LED strip connector is crucial for optimal performance, safety, and durability. A mismatched connector can lead to issues like flickering lights, overheating, or complete system failure. This guide explores the key aspects of LED strip connectors, including pin configurations, shapes, compatibility, and troubleshooting tips, to help both DIY enthusiasts and professionals select the best connector for their projects.

Pin Configurations: Understanding the Basics

The pin configuration of an LED strip connector determines the type of LED strip it can support, as different strips require specific connections for power, data, or color channels. Understanding these configurations is the first step in choosing the right connector.

Common Pin Configurations

- 2-Pin Connectors: Designed for single-color LED strips, such as white or monochrome lights, 2 Pin LED Strip Connectors feature one pin for power (positive) and one for ground (negative). These are ideal for simple lighting setups where color changes are not needed.

- 3-Pin Connectors: Used for addressable LED strips, such as WS2812B, these connectors include a data pin alongside power and ground. This allows individual LED control for dynamic lighting effects like animations or color patterns.

- 4-Pin Connectors: 4 Pin RGB LED Strip Connectors are used for RGB LED strips, which mix red, green, and blue to produce a wide range of colors. These connectors have pins for power, ground, and the three color channels.

- 5-Pin Connectors: For RGBW LED strips, which include an additional white LED for enhanced brightness or color accuracy, 5 Pin RGBW LED Connectors accommodate the extra channel, ensuring full functionality.

To choose the correct pin configuration, check your LED strip’s specifications for pin count and layout. Most strips indicate the number of pins and their functions, ensuring you select a compatible connector.

| Pin Count | Use Case | Example Connector Type |

| 2-Pin | Single-color LED strips | 2 Pin LED Strip Connector |

| 3-Pin | Addressable LED strips (e.g., WS2812B) | – |

| 4-Pin | RGB LED strips | 4 Pin RGB LED Strip Connector |

| 5-Pin | RGBW LED strips | 5 Pin RGBW LED Connector |

Connector Shapes: Functionality and Applications

The shape of an LED strip connector significantly impacts how you can design your lighting layout. Different shapes cater to specific installation needs, from straight runs to complex patterns.

Common Connector Shapes

- Straight Connectors: These connect LED strips end-to-end or to a power source/controller, making them ideal for linear installations like under-cabinet lighting.

- L-Shaped (Corner) Connectors: L-Shape LED Strip Connectors allow 90-degree turns, perfect for navigating corners or edges in applications like room perimeters or furniture accents.

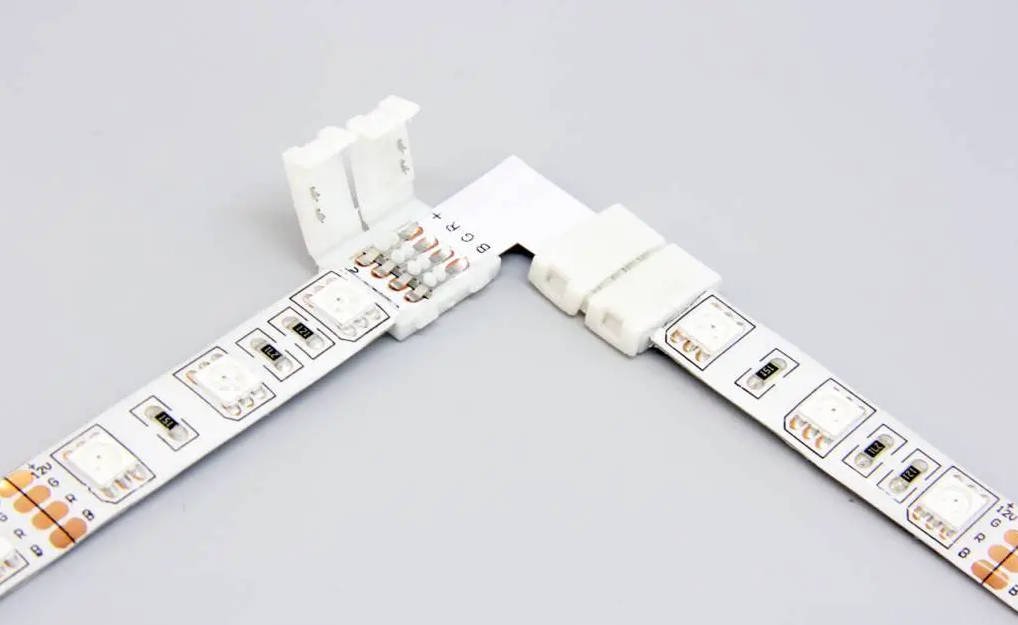

- T-Shaped Connectors: T-Shape LED Strip Connectors enable branching, splitting a strip into two directions for complex designs, such as in retail displays or signage.

- Flexible Connectors: Flexible LED Strip Connectors bend to fit curved or irregular surfaces, ensuring continuous connections in non-linear installations like curved walls or sculptures.

| Shape | Description | Use Case |

| Straight | Connects strips end-to-end | Linear installations |

| L-Shaped | Allows 90-degree turns | Corners, edges |

| T-Shaped | Splits strip into two directions | Branching designs |

| Flexible | Bends to fit curves | Curved surfaces, custom shapes |

When selecting a connector shape, consider your project’s layout and any obstacles requiring directional changes. For example, an L-Shape LED Strip Connector is essential for clean corner transitions, while a T-Shape LED Strip Connector suits multi-directional setups.

Compatibility: Ensuring the Right Fit

Compatibility is critical when selecting an LED strip connector. Mismatches in voltage, current, pin count, or strip width can lead to poor performance or damage.

Matching Connectors to LED Strips

- Voltage and Current: Connectors must match the LED strip’s voltage (e.g., 12V or 24V) and current requirements. Using an underpowered connector can cause overheating or failure.

- Pin and Width Compatibility: Ensure the connector’s pin count aligns with the strip’s configuration. LED strips typically come in widths of 8mm, 10mm, or 12mm, and connectors must match these dimensions. For instance, a 10mm connector won’t fit an 8mm strip properly (LED Strip Widths).

- Material Quality: High-quality connectors with copper contacts ensure reliable conductivity and durability, reducing the risk of connection issues over time.

Waterproof vs. Non-Waterproof Strips

For outdoor or humid environments, Waterproof LED Strip Connectors are essential. These connectors are designed to work with IP-rated strips, featuring seals to prevent moisture ingress. For indoor, non-waterproof strips, standard connectors are sufficient. Always verify compatibility with your strip’s coating or IP rating to ensure a secure connection.

| Strip Width | Common Connector Types | Notes |

| 8mm | Narrow connectors | Suitable for compact installations |

| 10mm | Standard connectors | Most common width for LED strips |

| 12mm | Wider connectors | Used for high-power or RGBW strips |

Common Issues and Troubleshooting Tips

Even with careful selection, issues with LED strip connectors can arise. Below are common problems and solutions to ensure a smooth installation.

Frequent Problems

- Connectivity Issues: Flickering or non-functional strips often result from loose connections. Ensure the connector is securely attached and pins align with the strip’s pads.

- Incorrect Wiring: For RGB or RGBW strips, incorrect pin alignment can cause wrong colors or no light. Verify the pin order (e.g., R-G-B-power) for your strip and connector.

- Compatibility Mismatches: Overheating or poor fit may indicate a mismatch in pin count, width, or power ratings. Double-check specifications before installation.

Troubleshooting Guide

- Test Connections: Use a multimeter to check continuity between the connector and strip to identify breaks.

- Re-seat Connectors: Remove and reinsert the connector to ensure a firm connection.

- Replace Damaged Connectors: Swap out any damaged or worn connectors to restore functionality.

- Consult Manuals: Refer to your LED strip and connector manuals for specific guidance (LED Strip Guide).

Conclusion and Recommendations

Understanding LED strip connectors is key to a successful lighting project. By selecting the appropriate pin configuration, shape, and ensuring compatibility, you can achieve a reliable and visually stunning setup. Solderless LED Strip Connectors simplify installation, making them ideal for DIYers, while Flexible LED Strip Connectors offer versatility for curved designs. For outdoor projects, Waterproof LED Strip Connectors ensure durability in harsh conditions.

Recommendations for Choosing Connectors:

- Identify your LED strip type (single-color, RGB, RGBW) to select the correct pin count, such as 2 Pin LED Strip Connector or 5 Pin RGBW LED Connector.

- Match the connector shape to your layout, using L-Shape LED Strip Connectors for corners or T-Shape LED Strip Connectors for branching.

- Verify voltage, current, and strip width compatibility to avoid issues.

- Test connections before finalizing installation and keep spare connectors for quick fixes.

By following these guidelines, you’ll create a professional and long-lasting LED lighting display tailored to your needs.