I. Introduction

In the realm of modern lighting systems, the significance of durable and reliable LED cable connectors cannot be overstated. Whether you are considering a custom LED cable connector for a specific application or looking for wholesale LED cable connectors, understanding how to optimize their durability becomes crucial. This article explores key considerations and strategies to ensure the robust performance of LED cable connectors, particularly in harsh environmental conditions.

II. Understanding LED Cable Connectors

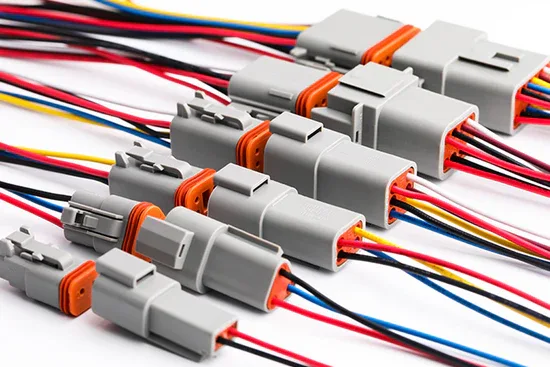

LED cable connectors play a pivotal role in the functionality of lighting systems, serving as the vital link between different components. They come in various types and specifications, catering to the diverse needs of users. Whether you are in the market for a custom LED cable connector designed for a specific application or looking to purchase in bulk from a wholesale supplier, grasping the fundamentals of these connectors is essential.

III. Challenges in Harsh Environmental Conditions

While LED cable connectors are integral components in lighting systems, they face significant challenges when exposed to harsh environmental conditions. Moisture, extreme temperatures, and dust are common adversaries that can compromise the performance and lifespan of these connectors. Whether you are considering a custom LED cable connector tailored for a specific environment or exploring wholesale LED cable connectors, it’s crucial to be aware of the potential challenges posed by the surroundings.

IV. Design Considerations for Durability

Addressing the challenges posed by harsh environmental conditions requires meticulous design considerations for LED cable connectors. Whether you are sourcing a custom LED cable connector tailored to specific needs or opting for wholesale LED cable connectors, the following factors are paramount:

- Robust Materials Selection: The choice of materials significantly influences the connector’s ability to withstand environmental stressors. Opting for robust and durable materials ensures longevity and resilience.

- Sealing Methods: Preventing moisture and dust ingress is critical. Implementing effective sealing methods, such as gaskets or IP-rated enclosures, shields the connector’s internals and enhances its resistance to external elements.

- Heat Dissipation Strategies: Extreme temperatures can impact performance. Incorporating efficient heat dissipation mechanisms ensures the connector operates optimally, even in challenging thermal conditions.

Whether you’re an end-user seeking a custom LED cable connector for a specialized application or a distributor in search of wholesale LED cable connectors, understanding these design considerations is key to ensuring the connectors meet the desired durability standards.

V. Reliability Enhancement Techniques

Ensuring the reliability of LED cable connectors involves implementing advanced techniques to handle various challenges and maintain consistent performance. Whether you are investing in a custom LED cable connector tailored for specific needs or considering wholesale LED cable connectors, the following techniques contribute to enhanced reliability:

- Proper Insulation and Shielding: To maintain signal integrity, proper insulation and shielding are imperative. These features protect against electromagnetic interference and environmental factors that can compromise the connector’s reliability.

- Overcurrent and Overvoltage Protection: Implementing protective features, such as overcurrent and overvoltage protection, safeguards the LED cable connector and connected devices from potential electrical issues, enhancing overall system reliability.

- Redundancy Features: Integrating redundancy features ensures continuous operation even in the face of component failure. This is particularly important in critical applications where uninterrupted connectivity is paramount.

For users seeking optimal reliability, understanding these enhancement techniques is crucial. Whether you’re in the market for a custom LED cable connector designed for specific applications or exploring wholesale options, these reliability measures contribute to a dependable lighting system.

VI. Testing and Certification

Ensuring the durability and reliability of LED cable connectors goes beyond design; rigorous testing and adherence to industry standards are essential. Users, whether they are looking for custom LED cable connectors or considering wholesale LED cable connectors, should prioritize connectors that have undergone comprehensive testing and certification processes.

- Industry Standards Overview: Familiarizing yourself with industry standards for LED cable connectors is crucial. Certifications from reputable organizations validate that the connectors meet specific performance and safety criteria.

- Third-Party Testing: Opting for connectors that have undergone third-party testing adds an extra layer of assurance. Independent assessments provide unbiased validation of the connector’s durability and reliability under different environmental conditions.

- Certification Labels: Understanding the meaning behind certification labels is vital. These labels signify compliance with specific standards and offer users a quick reference to the connector’s capabilities.

Whether you are an end-user seeking a custom LED cable connector for a specialized application or a distributor interested in wholesale LED cable connectors, prioritizing tested and certified connectors ensures a higher level of confidence in their performance.

VII. User Guidelines for Optimal Performance

Investing in durable and reliable LED cable connectors is just the first step; proper installation, maintenance, and adherence to guidelines are crucial for optimal performance. Whether you are a user installing a custom LED cable connector for a specific application or a distributor providing wholesale LED cable connectors, the following guidelines can help maximize connector lifespan and functionality:

- Installation Best Practices: Follow manufacturer guidelines for installation. Ensure connectors are securely fastened and positioned to prevent stress on cables and connections.

- Maintenance Tips: Regular inspection and cleaning are essential. Address any signs of wear, damage, or environmental exposure promptly. This proactive approach can prevent issues before they impact performance.

- Troubleshooting: Equip users with troubleshooting guides. In case of connectivity issues or anomalies, having clear steps to identify and resolve problems ensures a swift resolution and minimizes downtime.

Whether you’re a user looking for guidance on installing a custom LED cable connector or a distributor providing instructions for wholesale LED cable connectors, these guidelines contribute to a smoother and more reliable experience.

VIII. Case Studies

Examining real-world applications provides valuable insights into the performance of LED cable connectors in diverse environments. Whether you are an end-user exploring custom LED cable connectors or a distributor considering wholesale LED cable connectors, the following case studies offer practical examples:

- Outdoor Lighting Projects: Showcase instances where LED cable connectors were successfully deployed in outdoor lighting projects, highlighting their resilience against weather elements.

- Industrial Settings: Explore how LED cable connectors performed in challenging industrial environments, demonstrating their ability to withstand dust, vibrations, and temperature extremes.

- Infrastructure Installations: Present case studies involving LED cable connectors used in critical infrastructure projects, emphasizing their reliability in demanding conditions.

By examining these case studies, users gain a deeper understanding of how LED cable connectors perform in the field, assisting in informed decision-making when selecting connectors for specific applications.

IX. Future Trends and Innovations

The landscape of LED cable connectors is continually evolving, with ongoing advancements shaping the future of connector design and performance. Whether you’re an end-user considering a custom LED cable connector or a distributor exploring wholesale options, staying informed about upcoming trends is essential. Key trends and innovations include:

- Emerging Technologies: Explore new technologies influencing connector design, such as smart connectors with built-in monitoring capabilities for real-time performance assessment.

- Sustainability Practices: Investigate how the industry is embracing eco-friendly materials and manufacturing processes to create more sustainable LED cable connectors.

- Integration with Smart Systems: Understand how connectors are becoming integral components of broader smart lighting systems, enabling seamless integration with automation and control technologies.

As the LED cable connector landscape evolves, users can anticipate and leverage these trends to enhance the durability, reliability, and functionality of their lighting systems.

X. Conclusion

In the ever-expanding market for LED cable connectors, whether for custom applications or wholesale distribution, making informed choices based on design considerations, reliability enhancement techniques, and future trends will ultimately lead to a more resilient and reliable lighting infrastructure. Prioritizing durability and reliability is not just a necessity but a strategic investment in the performance and longevity of lighting systems in diverse and challenging environments.