Introduction

LED strip connectors play a crucial role in the functionality and reliability of LED lighting systems. However, their performance can be significantly affected by environmental factors. In this article, we will explore how various environmental conditions impact the longevity and performance of LED strip connector connections. We will provide insights for users to make informed decisions when selecting and installing these connectors.

Understanding Environmental Factors

Environmental conditions such as temperature variations, humidity levels, exposure to dust and debris, UV exposure, and chemical exposure can all profoundly impact the performance of LED strip connectors. Temperature fluctuations, for instance, can cause the expansion and contraction of materials, leading to the loosening of connections and increased resistance. Similarly, high humidity levels can accelerate corrosion, while exposure to UV radiation can degrade insulation materials over time.

Impact on Connector Materials and Construction

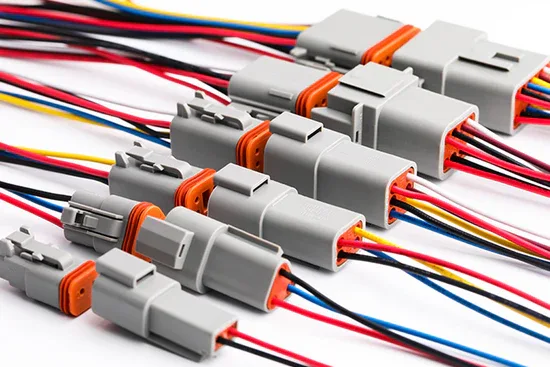

The materials used in LED strip connectors and their construction are crucial factors in determining their resilience to environmental conditions. LED strip connector manufacturers often use silicone, PVC, and polycarbonate, each offering varying degrees of resistance to temperature, moisture, and UV exposure. However, even with robust materials, environmental factors can still degrade connectors over time, emphasizing the importance of selecting connectors with appropriate IP ratings for specific applications.

Effects on Electrical Performance

Environmental factors can also have significant implications for the electrical performance of LED strip connectors. Corrosion and moisture ingress can increase resistance in electrical connections, leading to voltage drop and potential overheating issues. In addition, exposure to dust and debris may compromise the conductivity of connectors, affecting the overall efficiency of the LED lighting system.

Recommendations for Environmental Considerations

To mitigate the impact of environmental factors on LED strip connector connections, users should consider several key recommendations:

- Choosing Connectors with Appropriate IP Ratings: LED strip connectors are often rated according to their Ingress Protection (IP) level, indicating their resistance to dust and moisture. Users should select connectors with IP ratings suitable for the environmental conditions they will be installed.

- Implementing Proper Sealing and Protection Measures: In environments prone to moisture or dust exposure, it is essential to implement adequate sealing and protection measures for LED strip connectors. This may include using waterproof enclosures or sealing connectors with silicone or epoxy resin to prevent moisture ingress.

- Regular Maintenance and Inspection: Regular maintenance and inspection of LED strip connectors are vital for identifying and addressing any issues before they escalate. This includes checking for signs of corrosion, loose connections, or damage caused by environmental factors.

- Consideration of Environmental Conditions During Installation: During the installation process, users should consider the specific environmental conditions of the installation site. This includes avoiding locations exposed to direct sunlight or high humidity and ensuring proper ventilation to prevent heat buildup.

Case Studies or Examples

Let’s delve into some real-world examples that highlight the importance of environmental considerations for LED strip connector connections:

- Outdoor Lighting Installation: Using standard connectors, a company installs LED strip lighting in an outdoor patio area. Over time, exposure to rain and humidity causes corrosion, leading to voltage drops and flickering lights. By upgrading to waterproof connectors with higher IP ratings, the company effectively mitigates the effects of environmental factors, ensuring long-term reliability and performance.

- Industrial Application: In an industrial facility with high levels of dust and debris, LED strip connectors without adequate sealing experience frequent failures due to contamination. The facility significantly reduces maintenance costs and downtime associated with connector issues by implementing sealed connectors and regular cleaning protocols.

Conclusion

In conclusion, environmental factors can significantly impact the longevity and performance of LED strip connector connections. By understanding these factors and implementing appropriate measures, users can enhance the reliability and efficiency of their LED lighting systems. LED strip connector manufacturers are crucial in providing solutions tailored to withstand various environmental conditions, empowering users to achieve optimal performance in diverse applications.