Introduction

The world of RGB LED light strips has seen explosive growth in recent years, offering an easy and dynamic way to add lighting accents to homes, businesses, and entertainment setups. These versatile lighting solutions provide an array of colours and effects, making them a popular choice for various applications. However, the key to a successful RGB LED setup lies in selecting the suitable RGB LED light strip connectors.

In this article, we’ll explore the essential considerations for ensuring RGB LED connector compatibility with different types of light strips. For those in the market for connectors, we’ll provide insights on how to make informed choices, whether you’re dealing with voltage differences, communication protocols, or connector types.

Understanding RGB LED Light Strips

Before diving into the intricacies of connector compatibility, let’s first grasp the basics of RGB LED light strips. These flexible and adhesive-backed strips contain multiple LEDs, typically red, green, and blue (RGB). These can be individually controlled to create a broad spectrum of colours and lighting effects. The market offers an assortment of RGB LED strips, each with unique features and specifications.

RGB LED strips can be categorized into various types, including those designed for general ambient lighting, architectural lighting, or entertainment purposes like gaming setups and home theatres. Some are addressable, allowing control of individual LEDs, while others are non-addressable. Addressable strips offer intricate patterns and animations by manipulating each LED independently.

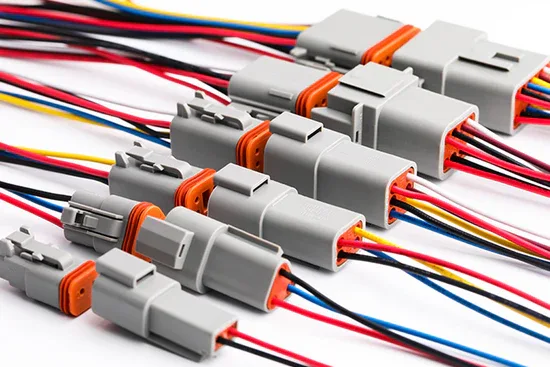

The significance of RGB LED light strip connectors becomes evident as they bridge these diverse strips to power sources and controllers. A failure in connector compatibility can lead to issues such as colour discrepancies, flickering lights, or even damage to your LED strips and components.

The Significance of Connector Compatibility

Connector compatibility is more than a technical concern; it’s the backbone of a hassle-free and visually appealing RGB LED lighting experience. Here’s why ensuring compatibility is paramount:

1. Seamless Functionality: Different RGB LED light strips have varying voltage requirements and communication protocols. Compatible connectors provide a seamless flow of power and data signals, allowing the strips to function harmoniously.

2. Visual Consistency: Incompatible connectors can lead to colour discrepancies among the LED strips. For instance, a connector mismatch may cause one segment to display a different hue or intensity than the rest.

3. Avoiding Flickering Issues: Flickering or unstable lighting can result from incompatible connectors. This not only affects the aesthetics but can be a source of irritation in daily use.

4. Component Protection: Incompatible connectors can overheat or damage the LED strips, controllers, or power sources. This can lead to costly replacements and system repairs.

Now, let’s delve into the factors that influence connector compatibility for your RGB LED setup. It’s important to understand these aspects before making a connector purchase.

Factors Influencing Compatibility

Voltage Requirements

Voltage is a fundamental factor when selecting RGB LED light strip connectors. LED strips come in various voltage specifications, with the most common being 12 volts and 24 volts. It’s crucial to match the connector’s voltage rating with that of the LED strip to ensure safe and consistent performance.

For instance, if your LED strip operates at 12 volts and you connect it to a 24-volt power supply via an incompatible connector, it can lead to excessive voltage, damaging the LEDs and posing safety risks.

Manufacturers often label the voltage rating on the LED strips and connectors, making it easier for users to match them appropriately.

Communication Protocols

RGB LED strips use different communication protocols to transmit data signals, controlling the colour and effects of the LEDs. The choice of connector should align with the communication protocol your LED strips and controllers employ.

Standard communication protocols for RGB LED strips include:

- PWM (Pulse Width Modulation): A standard and straightforward method of controlling LED brightness.

- SPI (Serial Peripheral Interface): Widely used for addressable LED strips, allowing precise control of individual LEDs.

- DMX (Digital Multiplex): Frequently used in professional lighting setups, offering extensive control over multiple lighting fixtures.

The RGB LED light strip connectors manufacturers and suppliers typically provide connectors designed for specific communication protocols. Ensure your connector choice matches the protocol used by your LED strips and controllers to maintain precise control.

Connector Types

RGB LED connectors come in various types, including 2-pin, 4-pin, and 5-pin connectors, each designed for specific applications and use cases. The number of pins often corresponds to the number of conductors required for power, ground, and data signals.

- 2-pin Connectors: Commonly used for single-colour LED strips, they provide power and ground connections.

- 4-pin Connectors: Suitable for most RGB LED strips, they include connections for power, ground, and two data channels.

- 5-pin Connectors: Used in addressable LED strips, accommodating power, ground, and three data channels to control each LED precisely.

Selecting the correct connector type is essential to ensure all connections are made correctly and consistently across your RGB LED setup.

Testing and Quality Assurance

To maintain the quality and compatibility of RGB LED light strip connectors, manufacturers implement rigorous testing and quality assurance protocols. This ensures that connectors meet industry standards and perform reliably in various settings. Understanding these processes can help users make informed decisions when choosing connectors.

Here are some critical aspects of testing and quality assurance for RGB LED connectors:

1. Voltage Testing: Manufacturers subject connectors to voltage testing to ensure they can handle the specified voltage without issues like overheating or power loss.

2. Signal Integrity: Ensuring data signals are transmitted accurately is critical for addressable LED strips. Connectors undergo signal integrity testing to confirm that data transmission is stable and interference-free.

3. Durability and Reliability: Connectors must withstand the rigours of daily use. Quality connectors undergo durability tests, including plugging and unplugging cycles, to assess their lifespan.

4. Material Selection: Choosing materials in connector construction affects performance. Manufacturers select materials based on electrical conductivity, heat resistance, and durability.

5. Industry Standards: Manufacturers adhere to industry standards such as UL (Underwriters Laboratories) and RoHS (Restriction of Hazardous Substances) compliance to ensure safety and environmental responsibility.

Knowing that the connectors have passed these tests and adhere to industry standards assures their quality and compatibility with your RGB LED light strips.

Connector Selection Tips

When it comes to selecting the suitable RGB LED connectors, here are some tips to guide your decision-making:

1. Research the Specifications: Before purchasing connectors, research and note down the specifications of your LED strips, including voltage requirements, communication protocols, and connector types.

2. Match Connectors to LED Strips: Ensure that the connectors you choose are compatible with your LED strips’ specifications. Check the voltage, communication protocol, and connector type to ensure they align.

3. Manufacturer Recommendations: RGB LED connectors often come from the same manufacturers as the LED strips. Following the manufacturer’s recommendations ensures compatibility.

4. Reputable Suppliers: Purchase connectors from reputable RGB LED light strip connectors suppliers. They are more likely to carry high-quality, tested products.

5. Seek Expert Advice: If you need more clarity about connector compatibility, seek advice from experts or online communities. Others may have faced similar challenges and can offer valuable insights.

6. Test Before Installation: Before permanent installation, test the connectors to ensure they work as expected. This can prevent potential issues after installation.

By following these tips and considering compatibility factors, you can make informed decisions when selecting RGB LED light strip connectors and avoid common pitfalls associated with connector mismatch.

Addressable RGB LED Strip Considerations

Addressable RGB LED strips have gained popularity for their ability to create intricate lighting patterns and effects by individually controlling each LED. However, they come with specific considerations for connector compatibility:

1. Specialized Connectors: Addressable RGB LED strips often require connectors with more pins to accommodate the extra data channels. These connectors may have 4, 5, or more pins, depending on the strip’s specifications. Ensure you have the correct connector type.

2. Data Signal Alignment: In addressable setups, precise data signal alignment is crucial. Misaligned connectors can lead to erratic lighting effects or non-uniform colour distribution. Carefully align and connect the connectors to avoid these issues.

3. Connector Durability: Addressable LED strips often undergo frequent colour changes and animations. This means connectors are repeatedly plugged and unplugged. It’s essential to choose connectors designed for high durability to withstand these demands.

4. Signal Amplification: For longer addressable LED strip installations, signal amplification may be required to ensure data signals reach all segments. Some connectors come with signal amplification features, simplifying this process.

5. Compatibility with Controllers: Ensure the connectors are compatible with the controllers you intend to use. Different addressable LED strips may require other protocols, so your connectors should support the specific protocol used by your strips and controllers.

Addressable RGB LED setups offer incredible lighting effects, but they demand careful consideration when selecting connectors to maintain compatibility and precision control.

Case Studies

To better understand the importance of connector compatibility, let’s look at a couple of real-world case studies:

Case Study 1:

Sarah was excited about setting up addressable RGB LED strips in her gaming room. She purchased high-quality LED strips but chose a connector without considering the communication protocol. When she connected the strips, they displayed random colours and patterns. She had to replace the connectors with the correct ones to get the desired lighting effects.

Case Study 2:

John purchased connectors from a reputable RGB LED light strip connectors manufacturer for his home lighting project. The connectors passed all industry tests, and his LED strips worked flawlessly. Even after a year of usage, he had no issues with connector compatibility, demonstrating the importance of quality assurance.

These case studies highlight the consequences of connector compatibility and the difference between informed choices and uninformed decisions.

Future-Proofing Connector Choices

The world of LED lighting is continually evolving with new technologies and standards. To future-proof your connector choices:

1. Stay Informed: Keep up with the latest developments in RGB LED lighting technology and connector advancements.

2. Consider Firmware Updates: Some connectors allow updates, enhancing compatibility with emerging technologies and features.

3. Evaluate Modular Connectors: Modular connectors may provide flexibility to adapt to new standards by simply replacing specific components.

By staying informed and adaptable, you can ensure that your RGB LED lighting system remains compatible with future technologies and standards, providing a dynamic and enduring lighting experience.

Conclusion

Selecting the proper RGB LED light strip connectors is crucial for a seamless and visually appealing lighting experience. Compatibility with voltage, communication protocols, and connector types is essential to avoid issues like colour discrepancies and flickering.

Testing and quality assurance protocols by manufacturers ensure that connectors meet industry standards and offer reliable performance. It’s also essential to research and match connectors to your LED strips’ specifications, seek advice when needed, and test connectors before permanent installation.

Addressable LED strips come with additional considerations, including specialized connectors and precise data signal alignment. Case studies demonstrate the impact of informed connector choices.

By future-proofing your connector selections, you can ensure that your RGB LED lighting setup remains compatible with emerging technologies and standards, providing a dynamic and enduring lighting experience.

In the ever-evolving world of RGB LED lighting, making informed connector choices is the key to unlocking a world of colour and creativity.