Introduction

JST connectors have earned a stellar reputation in the electronics industry for their precision, reliability, and adaptability. These connectors are especially favored in LED lighting applications, where secure and efficient power delivery is paramount. Among the diverse JST lineup, the JST XH connector and JST PH connector stand out as two widely utilized options. However, their distinct designs mean they cater to different needs and are not interchangeable. This article provides an in-depth exploration of the JST XH connector cables versus JST PH connector cables, highlighting their specifications, applications, and key differences. Our goal is to equip engineers, hobbyists, and procurement professionals with the knowledge to choose the right connector, with a special focus on why the JST XH series often emerges as the preferred choice for mid-power projects.

Overview of JST XH Connector Cables

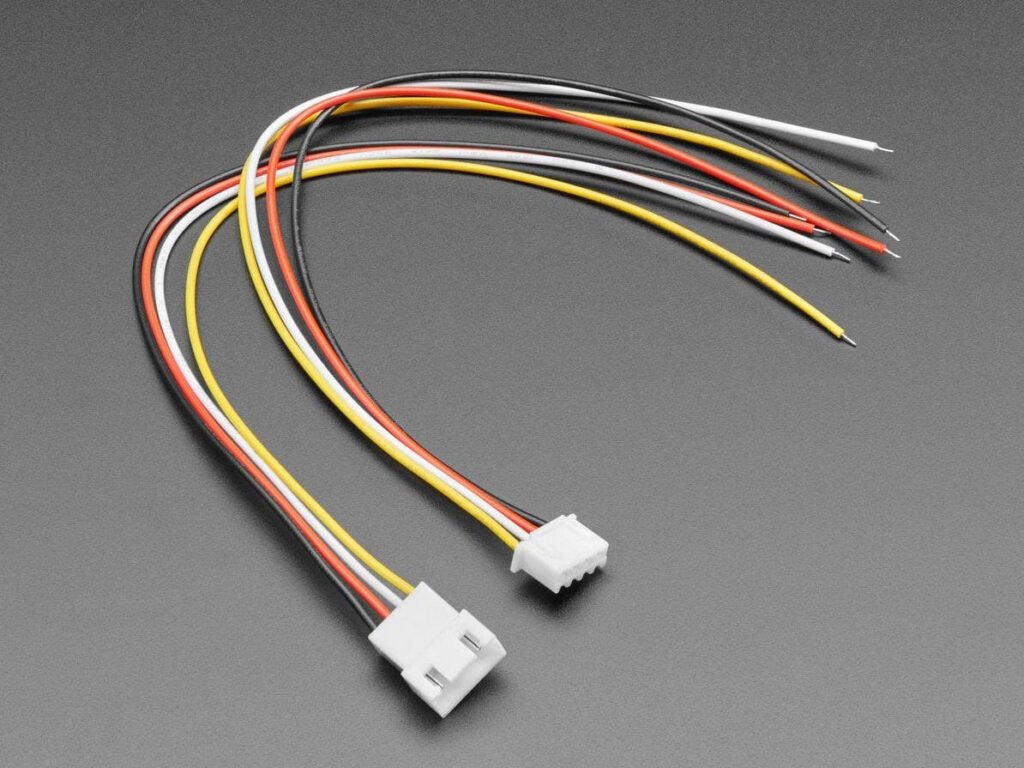

The JST XH connector is a wire-to-board connector engineered for robustness and versatility. Featuring a 2.5 mm pitch—the distance between adjacent pin centers—it offers a practical balance between compactness and ease of use. Its shrouded header design shields the pins from physical damage, while a latch mechanism ensures a firm, vibration-resistant connection. These attributes make it a top pick for applications requiring dependable power delivery.

Key Specifications

- Pitch Size: 2.5 mm

- Current Rating: Up to 3A

- Voltage Rating: 250V

- Mounting Height: Approximately 9.8 mm

- Locking Mechanism: Latch

Applications

- LED Lighting: Perfect for indoor setups, cabinet lighting, and LED strips, thanks to its ability to handle higher currents.

- Battery Packs: Ensures secure connections in rechargeable battery systems.

- Consumer Electronics: Powers devices like printers, scanners, and small appliances.

- Industrial Equipment: Reliable in machinery where stability is critical.

Advantages

- Durable Construction: The shrouded header and latch provide enhanced protection and connection security.

- Higher Power Capacity: A 3A rating supports more power-intensive devices.

- Flexible Configurations: Available in multiple pin counts and as JST XH cable assemblies or JST XH extension cables.

For example, in an LED strip installation, a JST XH connector cable can link multiple segments, delivering consistent power without the risk of disconnection, even during adjustments or movement.

Overview of JST PH Connector Cables

The JST PH connector is tailored for space-constrained applications. With a 2.0 mm pitch, it’s more compact than the XH series, and its lower mounting height of about 8.0 mm allows it to fit into tight spaces. It employs a friction lock mechanism, which is secure but less robust than the XH’s latch system, making it better suited for static environments.

Key Specifications

- Pitch Size: 2.0 mm

- Current Rating: Up to 2A

- Voltage Rating: 100V

- Mounting Height: Approximately 8.0 mm

- Locking Mechanism: Friction Lock

Applications

- Low-Power Devices: Common in laptops, tablets, and portable gadgets.

- Compact LED Lighting: Fits well in furniture or display case lighting where space is limited.

Advantages

- Small Footprint: Ideal for high-density, space-saving designs.

- Lightweight: Suited for portable electronics where weight matters.

- Cost-Effective: Uses fewer materials, reducing production costs.

However, its lower current and voltage ratings restrict its use in higher-power scenarios, making it less versatile than the XH series.

Key Differences Between JST XH and PH Connectors

Understanding the distinctions between JST XH connectors and JST PH connectors is crucial for selecting the right option. Here’s a detailed comparison:

| Feature | JST XH Connector | JST PH Connector |

| Pitch Size | 2.5 mm | 2.0 mm |

| Current Rating | Up to 3A | Up to 2A |

| Voltage Rating | 250V | 100V |

| Mounting Height | ~9.8 mm | ~8.0 mm |

| Locking Mechanism | Latch | Friction Lock |

| Pin Configuration | 2 to 16 pins | 2 to 16 pins |

| Wire Gauge | 22-28 AWG | 24-30 AWG |

| Typical Applications | LED lighting, battery packs, industrial equipment | Laptops, small electronics, compact lighting |

Why These Differences Matter

- Pitch Size: The 2.5 mm pitch of XH connectors simplifies soldering and handling, ideal when space isn’t severely limited. The 2.0 mm pitch of PH connectors suits high-density layouts.

- Power Ratings: XH connectors support higher currents (3A) and voltages (250V), making them suitable for LED strips or motors, while PH connectors are capped at 2A and 100V for low-power use.

- Locking Mechanism: The XH’s latch ensures stability in dynamic settings, unlike the PH’s friction lock, which is better for static applications.

- Wire Gauge: XH connectors accommodate thicker wires (22-28 AWG) for higher currents, while PH connectors use thinner wires (24-30 AWG) for lighter loads.

In essence, JST XH connectors excel in power-hungry, secure-connection scenarios, while JST PH connectors shine in compact, low-power designs.

Addressing Common User Questions

Here are thorough responses to frequent queries about JST XH connector cables and JST PH connector cables:

- Can JST XH and PH connectors be used interchangeably?

No, their differing pitch sizes (2.5 mm vs. 2.0 mm) and locking mechanisms make them incompatible. Using them interchangeably risks poor connectivity or damage. - Which is better for LED lighting projects?

For most LED setups, especially those with higher power needs like RGB strips, JST XH connectors are superior due to their 3A current rating and secure latch, ensuring reliable performance. - How do I identify JST XH vs. PH connectors?

- Visually: XH has a taller, shrouded header with a latch; PH is shorter with a friction lock tab.

- Pitch: Measure pin spacing—2.5 mm for XH, 2.0 mm for PH.

- Part Numbers: Look for XHP (XH) or PHR (PH) in JST codes.

- Are JST XH connector cables durable for long-term use?

Yes, with their latch mechanism and quality materials, JST XH connector cables resist wear, temperature changes, and humidity, ensuring longevity. - Where can I source high-quality JST XH connector cables?

Reputable suppliers like Fongkit offer certified JST XH cable assemblies and JST XH connector cable harnesses meeting TUV/CE/ROHS standards. - Can JST XH connectors be used outdoors?

Standard versions aren’t waterproof, but custom JST XH extension cables with IP-rated housings can handle outdoor conditions—check the IP rating. - What wire gauge works best with JST XH connectors?

Use 22-28 AWG wires; opt for 22 AWG near the 3A limit to reduce voltage drop and heat.

Why Choose JST XH Connector Cables?

JST XH connector cables offer compelling benefits, especially for LED lighting and mid-power electronics:

- Superior Power Handling

The 3A current rating supports demanding LED configurations without overheating risks. - Reliable Connections

The latch mechanism ensures stability, ideal for setups with movement or vibration. - Broad Applicability

From LED lighting to battery systems and industrial controls, JST XH cable assemblies adapt seamlessly. - Customization

Suppliers like Fongkit provide tailored JST XH connector cable harnesses with specific lengths and pin counts. - Value for Money

Though slightly pricier than PH connectors, their durability and power capacity offer long-term savings.

In a commercial LED project, JST XH connector cables minimize maintenance needs, enhancing efficiency and cost-effectiveness.

Practical Tips for Using JST XH Connector Cables

Maximize the performance of JST XH connector cables with these tips:

Selection

- Confirm Pitch: Ensure the 2.5 mm pitch aligns with your setup.

- Check Ratings: Stay within 3A and 250V limits.

- Environment: Use IP-rated JST XH extension cables for harsh conditions.

Installation

- Crimp Correctly: Use a JST-specific crimping tool for secure wire connections.

- Avoid Stress: Align connectors before pressing to prevent pin damage.

- Engage Latch: Confirm the latch clicks for a solid connection.

Maintenance

- Inspect Regularly: Look for wear or corrosion.

- Check Alignment: Misalignment can degrade performance—correct it promptly.

- Replace Promptly: Swap out damaged JST XH connector cables to avoid failures.

Sourcing

- Certified Suppliers: Choose manufacturers with TUV/CE/ROHS certifications.

- Custom Options: Opt for OEM/ODM services for bespoke JST XH cable assemblies.

Conclusion

When comparing JST XH connector cables to JST PH connector cables, the XH series stands out for its power capacity, secure latch, and versatility. Its 2.5 mm pitch and 3A rating make it ideal for LED lighting, battery packs, and industrial uses. By leveraging this guide’s insights and tips, you can optimize your projects for performance and reliability. For premium, customized solutions, connect with trusted JST XH connector cable wire harness manufacturers like Fongkit to secure high-quality JST XH extension cables tailored to your need